With A wide range of quality Aluminium Composite Panels (ACPs), Viva ACP has always been a frontrunner in the dynamic landscape of architecture.

Our state-of-the-art production lines and in-house labs, which conduct over 100 quality tests, allow us to offer exceptional Aluminium Composite Panel solutions that are not only durable and weather-resistant but also lightweight, low maintenance and easy to install.

However, in a move to further revolutionise the architecture industry, Viva ACP has joined hands with Aloxide, a leader in anodising technology. This collaboration has paved the way for exciting developments and opportunities for designers, architects and builders around the world.

Let us see what this partnership has to offer you.

Anodised Aluminium Composite Panels: A New Era of Durability and Style

Viva ACP and Aloxide have introduced anodised Aluminium Composite Panels in the market, offering a superior choice for modern building and construction projects.

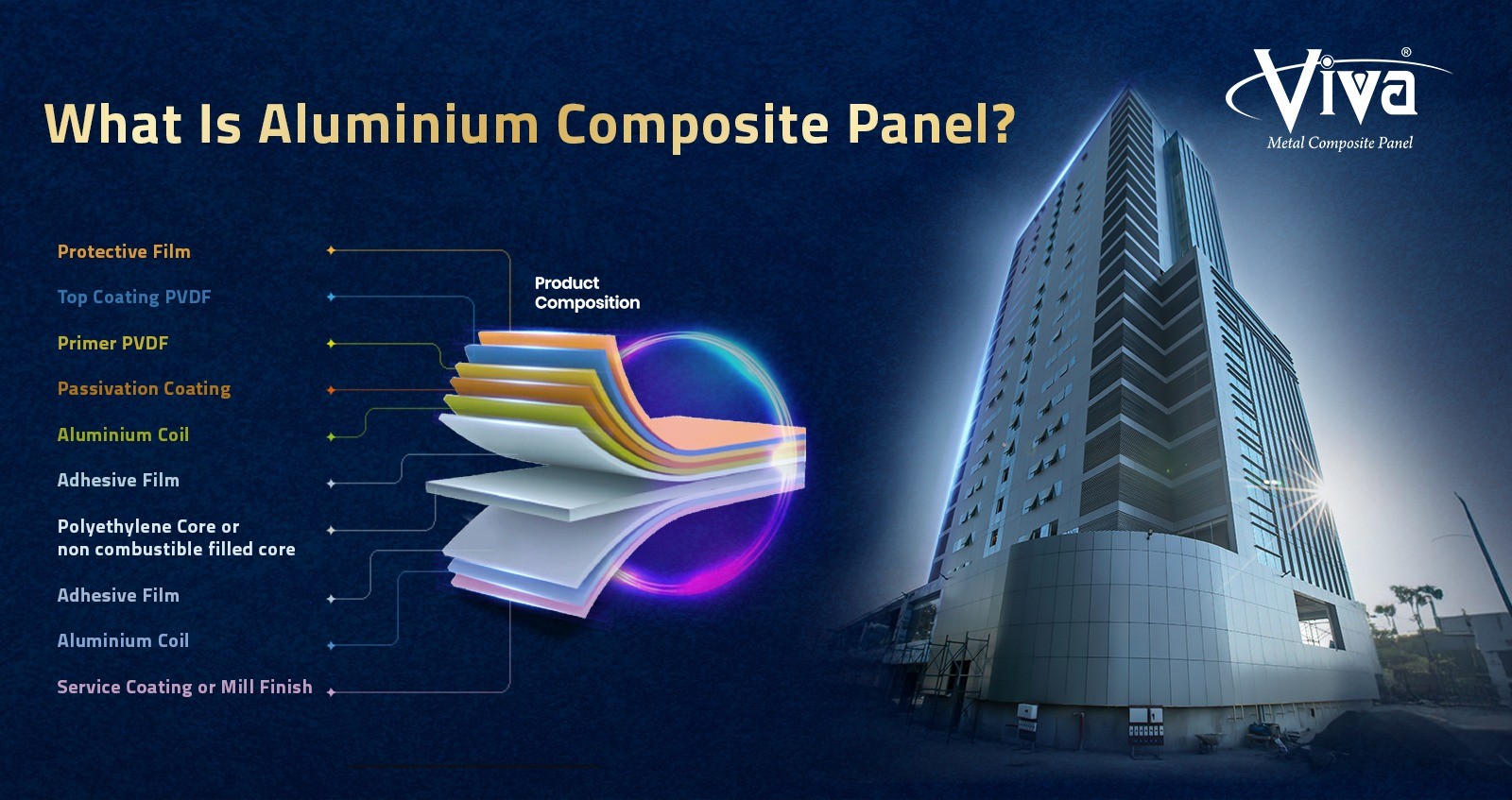

Just like Aluminium Composite Panels, anodized Aluminium Composite Panels are a type of panel that consist of a polyethylene core covered by aluminium sheets on both sides, however, the aspect that makes anodised ACPs unique is their anodised finish.

This finish is achieved by submerging the Aluminium Composite Panel in an electrolytic solution, which adds a protective layer to the aluminium surface.

Viva ACP Anodised ACPs: Stunning Shades to Explore

• Natural Standard Mill Finish: Ideal for projects seeking a classic, natural aesthetic.

• Gold G20 Standard Mill Finish: Adds a touch of luxury and sophistication, capturing the essence of timeless elegance.

• Copper 30 Standard Mill Finish: Reminiscent of aged copper, this shade has deep, earthy tones that provide a sense of heritage and charm.

• Bronze B30 Standard Mill Finish: Perfect for projects that demand both style and resilience.

• Natural Brite: Ideal choice for projects requiring a sleek and modern appearance.

Unique Features of Anodised ACPs

Increased Durability

The presence of a protective layer hardens the surface of anodised ACPs, making it resistant to wear and tear and scratches.

Better Weather Resistance

The thick porous layer on the surface of anodised Aluminium Composite Panels shields them from humidity, snow, extreme temperatures and harsh environments.

Easier Maintenance

The smooth surface of anodised ACPs prevents the accumulation of dirt or grime, reducing the need for frequent and deep cleaning. Moreover, anodised ACPs do not require paint, which eliminates the task of repainting.

Enhanced Corrosion Resistance and Anti-Tarnish

Anodising helps seal the pores of aluminium on the sides of Aluminium Composite Panels. This prevents the entry of water or any other corrosive substance and makes the anodised ACPs corrosion-resistant.

Aesthetic Appeal

The smooth finish and unique texture of the anodised ACPs give them a better aesthetic appearance and add a sleek and modern touch.

Longer Lifespan

Anodised Aluminium Composite Panels are highly resistant to weathering, extreme temperatures, abrasion and chemicals. This contributes to their long-lasting usage.

UV Resistance

The layer formed on ACPs after anodising is capable of absorbing UV radiation, making them UV resistant.

Colour Stability

Anodised ACPs do not get affected by UV exposure. This helps avoid panel fading and discolouration and ensures that the colour and appearance of anodised Aluminium Composite Panels remain the same even after years.

Viva ACP and Aloxide: The Panel Partners

The fusion of Viva’s extensive collection of Aluminium Composite Panels with the anodising technology used by Aloxide has given birth to a range of unmatched and superior-quality anodised ACPs.

With us, you can take your architectural projects to the next level and get premium Aluminium Composite Panels with unrivalled corrosion resistance, long-lasting colours, easy maintenance and installation and a sleek finish.

Regardless of your needs, be it signages, building facades, or interior design, we are here to help you with our innovative anodised Aluminium Composite Panels.

Why Choose Viva ACP?

● 20+ years of manufacturing experience

● 12 production lines

● 300+ shades with an option for customisation

● 4 colour coating lines

● 100+ quality tests

Anodised ACP Project Highlights

● The Twist Bridge, Norway

● Curve, Saint-Denis, France

● ADMI AHOI, Hamburg, Germany

● The Greenlaw Works, Business Center, United Kingdom

● Salle Evenementielle Muret, France

Conclusion

The partnership of Viva ACP and Aloxide marks a milestone in the industry. The combination of top-notch Aluminium Composite Panels with anodising technology has given impressive results that redefine and enhance the features of ACP.

As industry leaders, Viva ACP and Aloxide have become the go-to choice of designers and architects looking for unparalleled durability and aesthetic appeal that can take their creative visions to unprecedented heights.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French