Exposure to UV rays and pollutants, moisture and humidity, improper installation, improper maintenance and poor-quality materials are all factors that lead to aluminium composite panels discolouring and peeling. A product like the ACP sheet, which stands out as the most modern and sophisticated building material for both the present and the future, could often be seen suffering from this fading problem.

Though opting for a leading producer ensures the usage of high-quality raw materials in the manufacturing process, it still does not make your aluminium composite panels invulnerable to harsh UV radiation. The negative impacts of sunlight and other environmental instigators could be noticed in prominence sometimes just after 1 year of installation, despite the use of new weather-resistant additives.

Viva, a leading company in the cladding industry both nationally and internationally is now trusted as the go-to partner for shaping the skylines of tomorrow: we have introduced a paint formulation and coil coating process that has effectively solved the issue of ACPs waning away. As a trendsetter in strength, style and safety in the metal composite panel market, we are pioneers in setting up 3 colour coating lines in India, thus providing the highest quality assurance in various real-time weather-related scenarios.

What Causes Aluminium Composite Panel Fading In India?

The reasons causing ACP fading in India are plenty. The first major problem that the cladding industry here suffered from since its inception 15-20 years ago, was the lack of quality control over the products. This is primarily because ACP sheets were imported back then. Hence, the companies here could not influence the first two phases of ACP manufacturing: paint formulation and coil coating. Thus, the coating lines were not in place.

80% of ACP fading takes place due to poor quality of paint and the other 20% happens due to lack of maintenance. When the coils were brought in mainly from China, the quality and the process involved could not be supervised, thus resulting in coated cladding materials that were unable to cope with the harshness of UV rays.

A flawed panel that has gaps and cracks is susceptible to moisture. The improper installation also leads to deterioration, discolouring and peeling. Thus, going for an established manufacturer that is well-reputed in front of both its customers and competitors is always a safe choice, as it ensures the usage of top-notch raw materials, seamless installation and exceptional after-sales service.

How Did Viva Produce ACP Sheets That Are Immune To Climate Factors?

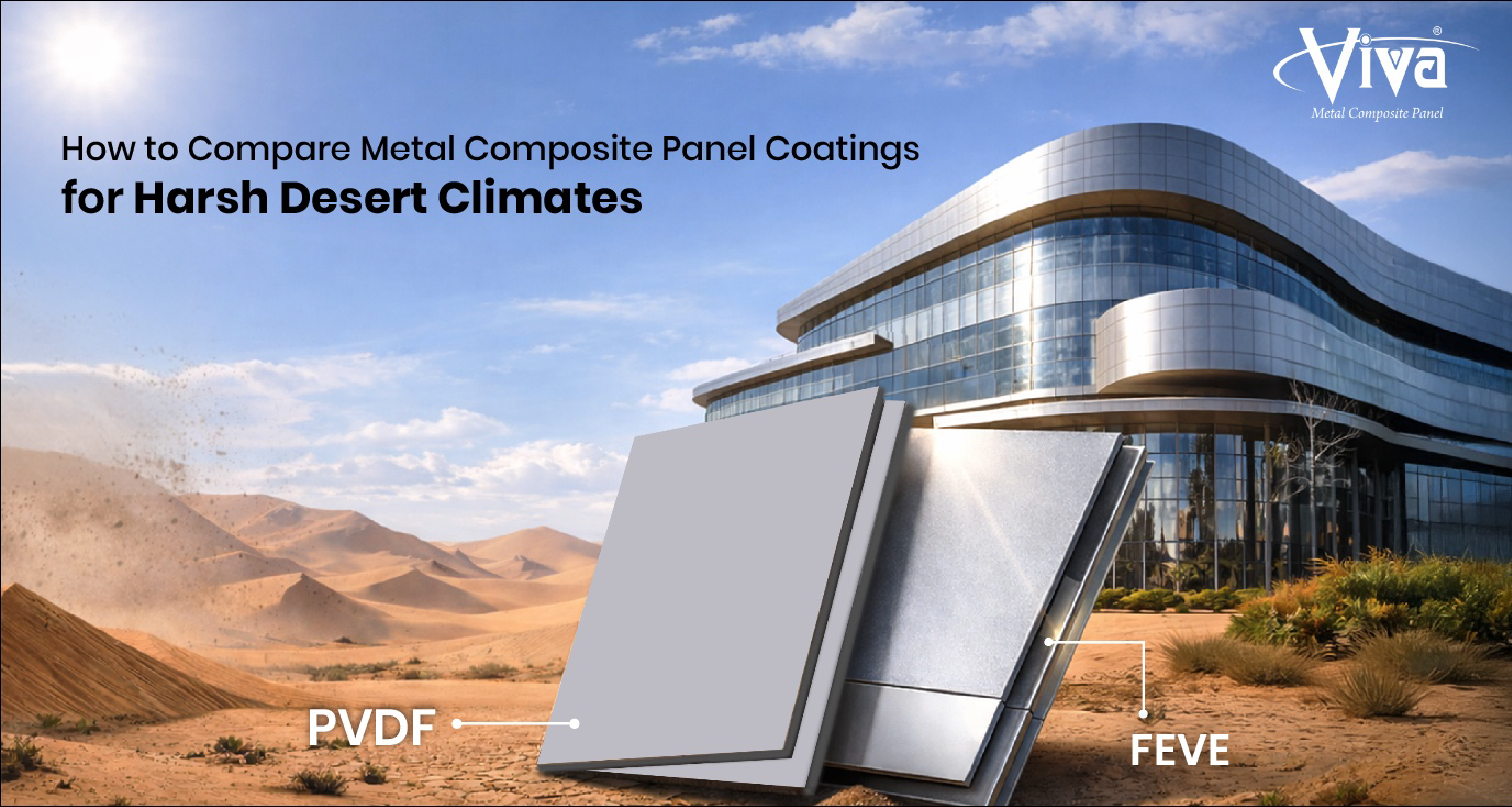

Viva, equipped with a complete in-house manufacturing process has total control over all the 3 phases of ACP production: paint formulation, coil coating and lamination. Instead of using polyester and super durable polyester paint, we deploy PVDF or Polyvinylidene Fluoride paint to ensure our cladding material is coated with the right paint to protect your building from the harshness of the UV rays.

Besides this paint formulation, Viva being the trendsetter in the industry also executes the application of paint on the aluminium coil in its in-house manufacturing plant, thereby putting in place stringent quality control measures to achieve the highest quality standards. While applying the paint to the coil, we use our state-of-the-art colour-coating lines (CCL)- the first of which was commissioned in 2018, the second in 2021 and the third in 2023 to solve the ACP fading problem.

Supplying safety, style and strength in cladding, this unique 3 ACP colour coating unit is right now not just paving the way forward in India but also abroad. The first colour coating line- a single-coat and single-bake coating line is capable of coating one colour and baking one colour at a very precise temperature. The second coating line is the three-coat two two-bake coating line that allows three coats and two times baking can cover up to a width of 1670mm, thereby even beyond 5ft. The third coating line is a state-of-the-art three-coat three-bake coating line that also covers a width of 1670mm. Thus, with each of our coating lines being an upgrade over the previous, we make sure that the entire sheet including its strength and visual aesthetics (colour, texture, grain and finish) remain not just protected from UV rays and other environmental factors but also effective for decades to come. We are not stopping here: our 4th coating line is set to launch by the end of this April, which will specialise in the coating of 2mm and 3mm solid sheets.

You may like: Bringing Color To Life: Discovering Viva ACP’s In-House Coating Line

Viva: The Trendsetter In Cladding and Architecture

Steadfast in their commitment to customer satisfaction our exterior applications don’t just merely protect your building; they transform the space. The leading aluminium composite panel manufacturer in India, our massive range of products starting from our series of aluminium composite panels to unique innovations such as zinc composite panels, copper composite panels , and aluminium honeycomb panels are all engineered with the 3 ACP colour coating unit to ensure that your building never lets you down on style, safety and strength.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French