Designers, architects, façade contractors, and business owners have a variety of cladding materials to choose from, but the one that stands out in the competition is ACP cladding.

The ACP cladding is made of ACP sheets, better known as Aluminium Composite panels, the sheets have remarkable properties that make them the right choice among designers for adding structural strength to the building.

ACP is the new-age material that has crowned itself in one of the most luxurious buildings in the world; "Burj Khalifa". The multi-storey tower has parts of ACP cladding that enhance the overall outlook of the gigantic building.

Architects across the world are accepting ACP panel for urban commercial and residential complexes as it is visually aesthetic and has tremendous strength. Apart from this, it has a range of other characteristics, which we will discuss elaborately in this blog.

How Aluminium Composite Panel(ACP) Enhances Strength?

Thermal resistance, fire resistance, anti-corrosion, and flexibility are four components that help in enhancing the strength of the ACP sheets.

Thermal Resistance

The ACP panel is installed in which the top and bottom remain open. This helps in building an air cavity where the air can flow. Thermal resistance is the property of the panels to resist heat and enhance durability of the panels.

It resists the heat penetrating the walls of a building, which prohibits structural damage due to overheating of the walls. The gap in the panels traps the heat that helps in maintaining the temperature in summer and winter.

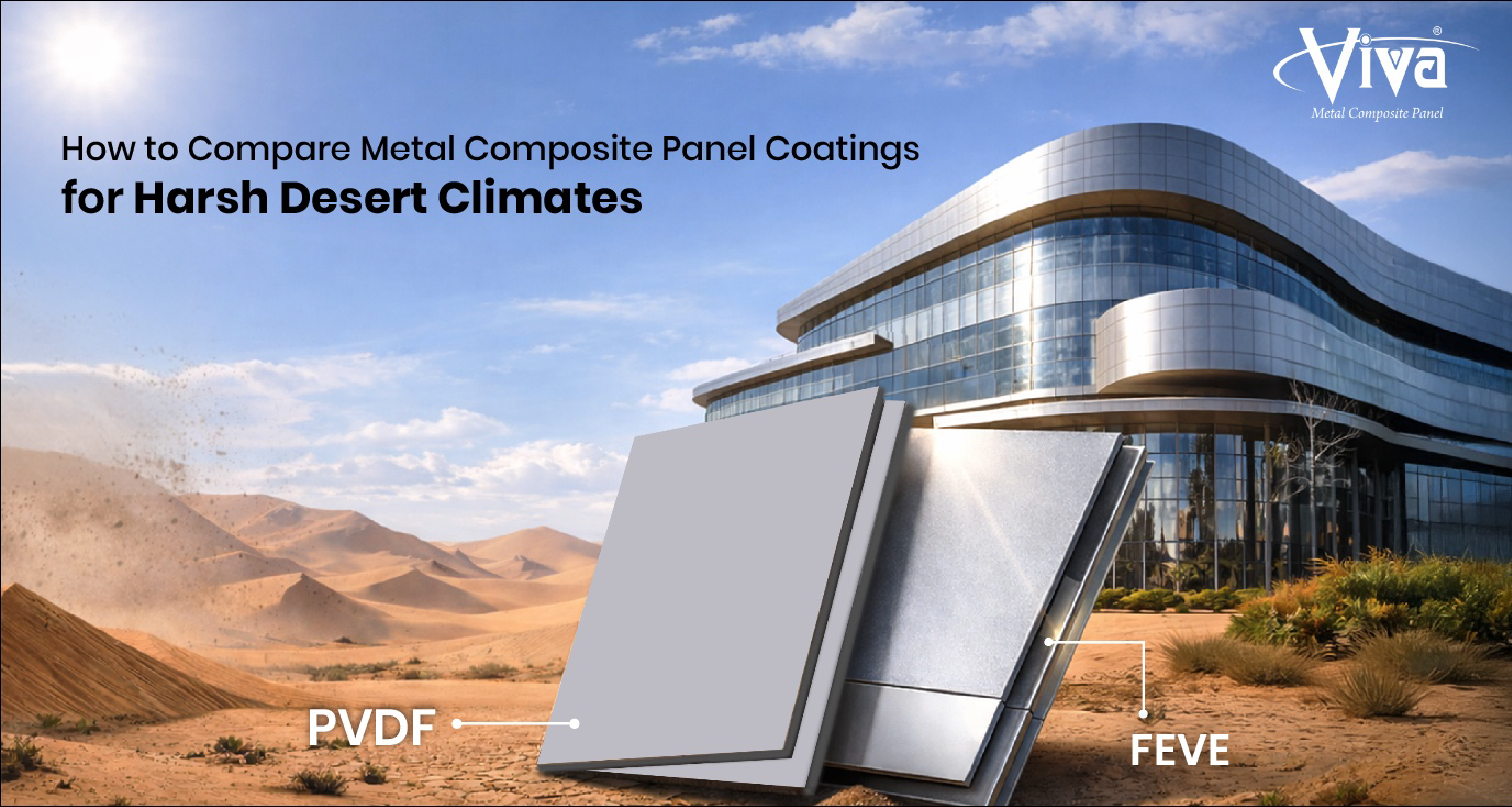

Moreover, Viva's Aluminium composite panel has a high grade of thermal resistance, it comes from the PVDF/FEDE coating. It ensures the walls are well protected and reduce the chance of damage within the walls.

Fire-Resistance

The ability to resist fire is another factor that helps in enhancing structural strength. The core of Viva ACP is manufactured in the design of a Honeycomb panel which prevents fire penetration into the core and is the reason behind igniting a fire in the building.

Our panels have the highest accreditation of fire safety, i.e, NFPA 285. The Heat Transmission Coefficient is 5.53 W/m2 K which helps the spread of fire and reduces its intensity. The vacuum created by the air bubbles due to the honeycomb core design doesn't let the fire spread further.

Moreover, it does not produce any toxic gas or vapor during a fire breakout, which eases the evacuation procedure. The panels ensure there will be minimal damage to the building structure and give ample time to take the necessary step to stop the fire completely.

You May Like: Fire Retardant ACP Panels and Why Are They Important

Anti-corrosion

The primary application of aluminium composite panel is exterior façade/cladding, signage wall partition, and building elevation. These are mostly exterior work, which means they are largely exposed to heavy moisture and rainfall.

If the moisture remains in for prolonged contact with aluminium it leads to damage to the outer layer and leads to rusting. To prevent it, ACP panels undergo powder coating during the manufacturing stage. It ensures the sheet remains unaffected by the moisture and enhances its life span of the sheet.

As the sheet is anti-corrosion, it does not allow water to settle or penetrate between the walls, which prevents dampness or formation of mold into the wall leading to structural damage. Hence, it adds strength to the overall structure.

Conclusion

Viva is a leading ACP sheet manufacturer in India. It is one of the leading exporters of ACP across 25 nations, and it aims to grow its network in the upcoming years.

Viva's aluminium composite panel is known for features such as durable, cost-efficient, and aesthetic design. To know more about Viva, visit their official website today.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French