Contemporary home design has grown over the last few years and a sleeker, modern aesthetic will rule in the coming years. To achieve the look of modern aesthetics, the two cladding material which is in rage in the modern architectural world is HPL and AHPL sheet.

These two sheets might have a similar visual appearance but have numerous differences. If you are curious to know which one is better cladding material then read along to know about their differences.

AHPL Sheets

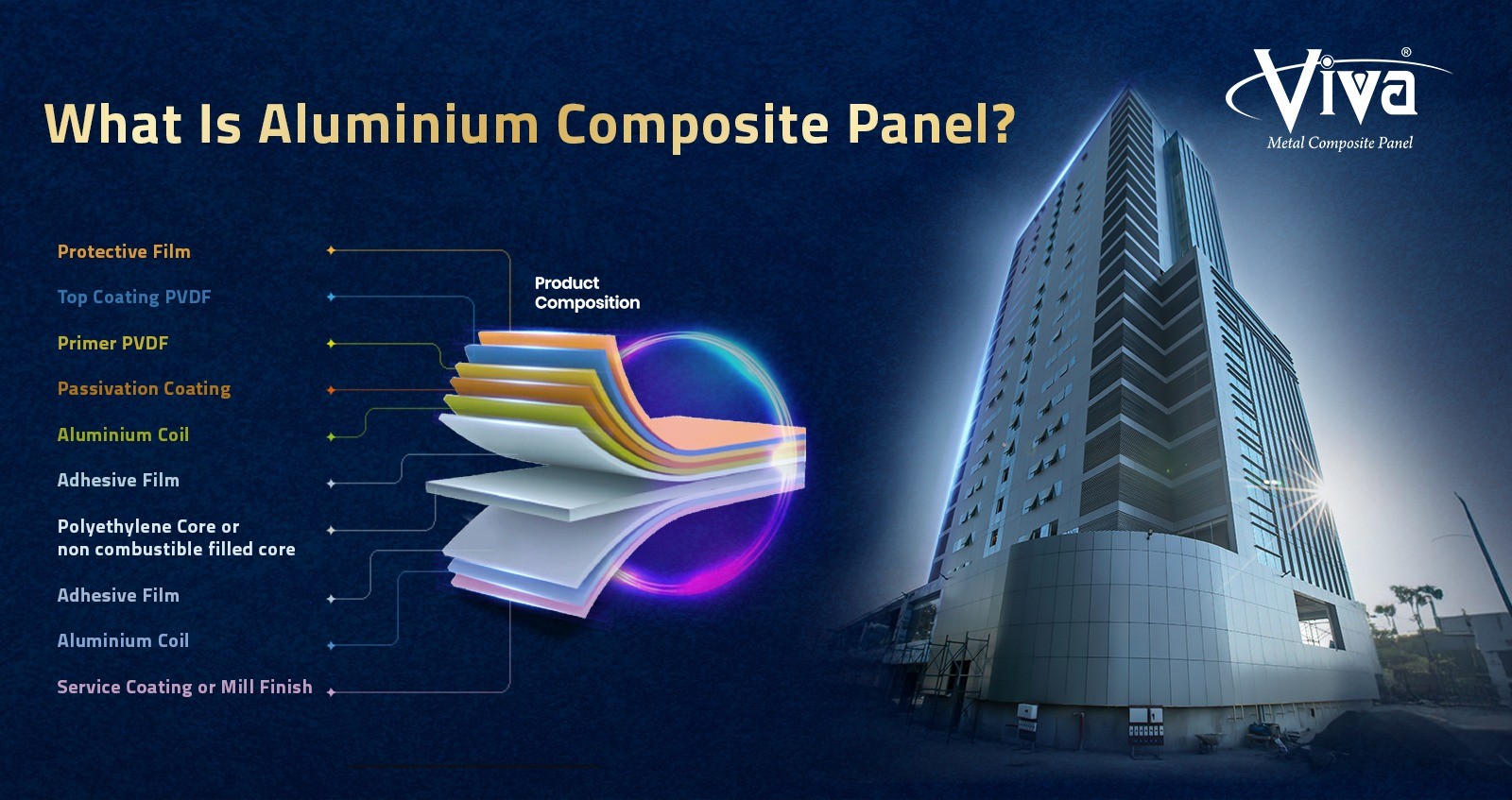

AHPL's full form is aluminium - high-pressure laminates. This cladding material is manufactured from the aluminum coil, which makes it superior in quality in comparison to paper HPL board. These sheets are 90 degrees bendable and easier to fabricate.

HPL Sheets

The HPL sheets, also known as high-pressure laminates constitute 70% of the paper in the core and the rest of the part has thermosetting resin that enhances the strength of the

HPL sheets.

The Major Difference Between the AHPL Sheet and HPL Sheet

Difference in Coating

The HPL board or HPL sheet has a UV coating that gives it a glossy finish and stain-resistant features. In this the texture or design is applied to a printed paper surface, this paper hardens when cured under ultraviolet light. However, this is not effective for metallic finishes or 3-D illusion finishes.

AHPL has

FEVE/PVDF coating or powder coating that enhances properties like resistance to weather change, and corrosion. AHPL comes in a range of shades and textures that help in enhancing the aesthetic of the exterior of a building.

Quality of the Sheets

The HPL board or normal HPL is not resistant to high pressure or impact, scratch or abrasion resistant, neither it is immune to bacteria or fungal attacks. Needless to say, the lack of these features makes it susceptible to damage. Hence it does not depict high quality after a while.

Whereas, Viva's AHPL sheets are resistant to high pressure, or impact, it does not react to moisture and stain. Viva’s AHPL features zero moisture absorption and has termite and bacteria-proof sheets, which makes it superior in quality when compared to paper-based HPL sheets.

Maintenance

The HPL sheets are susceptible to damage, this makes them difficult to maintain. The dirt and stain are not easy to clean from the surface of the HPL board as it has a UV coating. Moreover, changing a single sheet of HPL board is difficult compared to AHPL sheets.

AHPL sheet is resistant to dirt or stain. It can be cleaned with wet wipes, this makes it easier to maintain in long run. If damaged, a single sheet of AHPL can be replaced with a new one, as it is attached with rivets and nuts.

Difference in Installation

HPL sheets are also heavier, but, do not bend 90 degrees, this makes it difficult to install in sidings or spaces which need the material to bend.

AHPL sheets are easy to install as it has aluminium base, and it is 90 degrees bendable. It can be fixed on the siding of the wall or in spaces that require an L-Shape in design.

You May Like: Why Choose ACP for High Rise Building

Conclusion

AHPL is superior material compared to an HPL sheet, the factor that makes it better is the resistance to crack, better designs, and 90-degree bendability.

Viva is one of the premier manufacturers of AHPL sheets and

ACP sheets. ACP and AHPL sheets have strong physical properties that make them superior cladding materials.

The shades offered in Viva's AHPL series are- Sparkle White, Tiger Black Marble, Ferrari Red, California Rustic, Armani Black, Natural walnut, Chic Paradigm.

Whether you want to incorporate an AHPL sheet or ACP sheet, Viva provides cost-effective and acoustic sheets for your home.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French