Dubai is a land of architectural wonder. With globally renowned structures like Burj Khalifa, Jumeirah Burj Al Arab, Cayan Tower, Dubai Frame, Museum of the Future, and Jumeirah Emirates Towers, it’s no wonder engineers are always looking for new design trends. And if we consider function, aesthetics, and sustainability, perforated metal panels are carving out their niche.

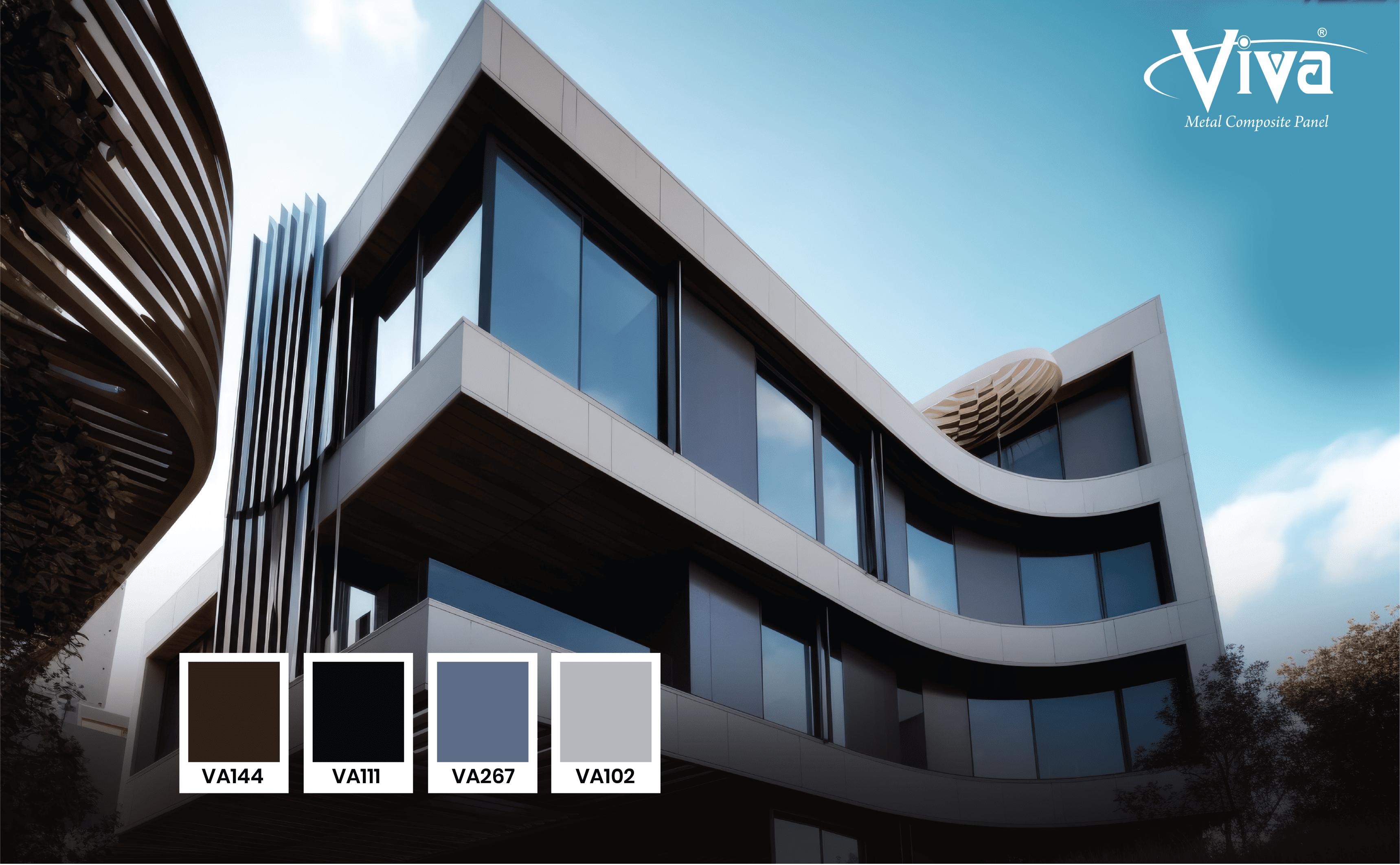

From skyscrapers to commercial hubs, these lightweight yet durable panels have the potential to redefine how buildings look. At Viva, we specialize in custom aluminium perforated metal panels, engineered to meet the region's demanding environmental conditions and diverse design needs. Whether you're an interior designer planning an open-plan office or a contractor looking to clad a shopping mall façade, our tailored panels offer a reliable solution.

Why Choose Perforated Aluminium Panels?

From the outside, perforated panels look like a sheet that’s been stamped or punched to create different hole sizes, shapes, and patterns. However, the punching holes are not just randomly made; they show technical precision, design flexibility, and structural strength. In a city like Dubai, where almost every building is sky-high, choosing durable materials becomes a top priority. However, if the metal is too heavy, it might increase the installation cost.

Aluminium thus has become the top raw material for perforable metal panels. The metal is light-weight, corrosion-resistant, malleable, non-magnetic, and sturdy. Its unique properties make it suitable for Dubai’s arid coastal environment.

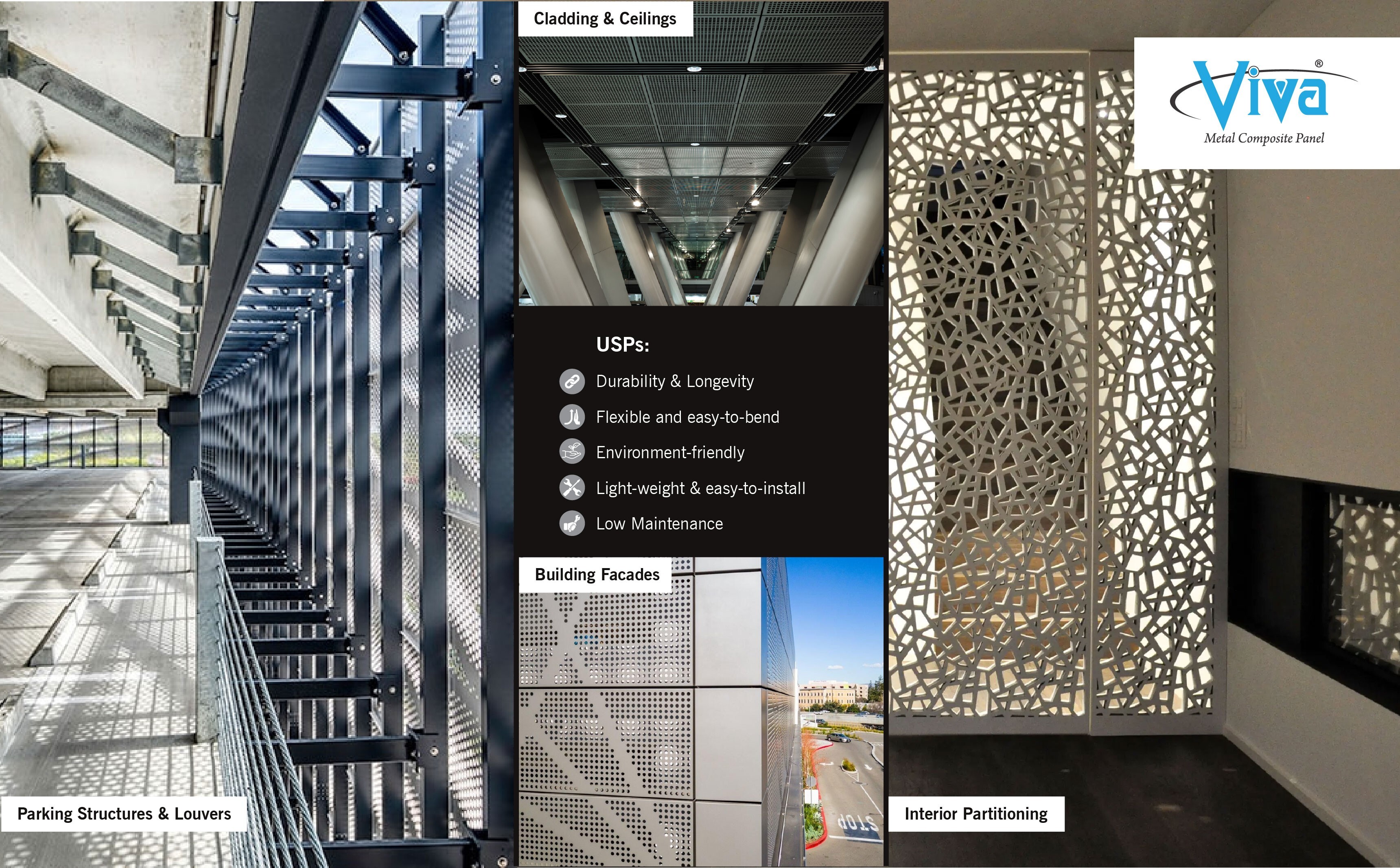

● Durability & Longevity: Aluminum composite panels are well-known in the commercial construction sector for being durable. Using these for perforation increases the overall lifespan of the structure.

● Flexible and easy-to-bend: Perforated aluminium sheets are surprisingly flexible, but their ability to bend cleanly depends on two key things: the sheet’s thickness and the size and spacing of the holes.

● Environment-friendly: Constructing in a city like Dubai, aiming for eco-consciousness and promoting sustainability, aluminum composite panels have become a well-accepted raw material. The panels are recyclable and can be reused again and again.

● Light-weight & easy-to-install: For high-rise buildings, installation can become a pretty big deal. It adds up to the labour cost if the material is too heavy. ACPs are lightweight, which makes them much easier to install. Plus, using these panels reduces the overall weight of the overall structure. Hence, stress on the foundation and lower floors is minimized, which makes the construction more efficient and cost-effective.

● Low Maintenance: With the buildings in Dubai reaching up to the sky, cleaning and repairing can become a major hassle. ACP panels, on the other hand, are durable and easier to clean. Especially, Viva’s ACP panels coated with fluorocarbon PVDF paint using advanced nanotechnology offer self-cleaning.

How Are Perforated Metal Panels Made?

Here’s a brief on how perforated metal panels are generally made

1. Preparation: The first step is to pick high-grade aluminium sheets and clean them thoroughly. This is necessary to remove any oils or residues that might interfere with punching or finishing.

2. Pattern Selection: This is where architects and designers get to explore their creativity. They can choose a design from the existing ones or ask to develop a new pattern. Whether you want better ventilation, sound absorption, light diffusion, or just pure aesthetics, we can match your preference.

3. Precision Punching: ACP panels go through CNC-controlled punching presses to stamp the pattern onto the sheet with impeccable accuracy. The technology allows no room for error, which is critical in commercial-scale projects.

4. Finishing: Once the punches are done, the final step is to trim the sheets to your required dimensions and deburr edges for safety. Designers can choose from our multiple finish options based on their preference and project requirements.

Commercial Applications of Perforated Metal Panels

The commercial sector prefers niche designs that are also durable and need less maintenance. Viva’s perforated aluminum panels can be used in multiple spaces, such as:

1. Building Façades

Dubai’s skyline isn't dull. With Viva’s perforated panels, contractors can add depth, shade, and pattern to any façade. Besides curb appeal, the micro-perforations improve airflow, reduce solar heat gain, and add a layer of privacy without blocking light.

2. Interior Partitioning

Open offices, retail spaces, and hospitality environments often require partitions that provide both separation and transparency. Perforated panels are the sweet spot between enclosure and openness—ideal for modern interiors that demand both aesthetics and acoustic control.

3. Parking Structures & Louvers

In the UAE’s heat, parking garages must be ventilated yet safe. Our custom panels offer security, shade, and airflow—plus a sleek metallic finish that aligns with contemporary urban design.

4. Cladding & Ceilings

Elevators, malls, airports, showrooms, and aluminium panels with custom perforation can be installed on ceilings and walls to enhance both air circulation and visual dynamism.

Final Thoughts

In the commercial construction industry, design preferences are always shifting from one to another. But one thing that remains constant is the demand for convenience. Perforated metal panels have gained popularity not just for their aesthetic vibe but also for their convenience, like better ventilation, light control, and acoustic properties. Using aluminum for perforation increases the panel's lifespan while reducing maintenance costs.

With over 20+ years of experience, state-of-the-art machinery, and a dedicated project coordination team, Viva ensures timely delivery on bulk orders, customization at scale, on-site consultation, and after-sales support.

FAQs

Q.1. Where are perforated metal panels used in architecture?

Perforated metal panels are used for building façades, interior partitions, ceilings, cladding, louvers, and parking structures.

Q.2. Why is aluminium preferred for perforated metal panels in Dubai?

Aluminium is lightweight, corrosion-resistant, recyclable, and suitable for extreme weather. In Dubai’s coastal, high-rise environment, aluminium offers the durability needed for long-term projects without adding structural load or requiring frequent maintenance.

Q.3. Are perforated aluminium panels customizable?

Yes. At Viva, we offer custom perforated metal panels where clients can select patterns, hole sizes, shapes, and finishes to match their specific design goals, be it for ventilation, aesthetics, branding, or light control.

Q.4 Do installing perforated panels reduce heat in Dubai’s climate?

Yes. Micro-perforated façades can reduce solar heat gain by allowing natural airflow and diffused light, lowering the need for artificial cooling and improving energy efficiency in buildings.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French