When it comes to structural integrity and unparalleled fire safety, Aluminium Composite panels outrun any other material. In this post, we will discuss fire-safe building materials. One of them is fire retardant ACP. ACP consists of two high-strength aluminum sheets which sandwich a low density, insulating core. Hence, they are also known as sandwich panels. The core material contains a non-combustible mineral and a small fraction of thermoplastic which ensures high performance against fire hazards.

Evolution of Aluminium Composite Panel

The Aluminium Composite Panel was originally introduced as a joint invention between companies known as Alusingen and BASF in 1969. In spite of its introduction in the 1960s, it was only until the mid-1980s that the mainstream architectural industry discovered the properties of ACP as a building material, and started its extensive use. The commercial usage of ACP in residential buildings happened only in the 1990s as it was realized that it would reduce costs and enhance architectural performance.Aluminium Composite Panel Brands

The first form of ACP was marketed under the brand name ‘Alucobond®’, whose manufacturing process was patented by Alusingen for 20 years between 1971 and 1991. The original composite panels were known as Alucobond. After the patent expired, many important names of the construction industry began the ACP manufacturing process. VIVA FR ACP in India is one of the leading manufacturers of these panels. It’s a company of prestige in the Veneer and ply industries with a proven track record of experience. VIVA is an ISO 9001-2008 and ISO 14001:2004 and “CE” certified company set up in 2005 at Mumbai, Maharashtra. The manufacturing facility has a state-of-the-art quality machine and has an integrated infrastructure and a talented pool of professionals operating it. With the two advance and ultra-modern ACP lines, the total production capacity is 4 million sqr. Meter per annum. During the last 10 years, Viva has established its brand as the preferred, spreading it’s business pan India. Viva high-quality aluminum composite panels are available in large varieties. The aluminum composite panel or ACP panel have popular eye appeal, unmatched quality, style, and durability. It has good insulation, low thermal conductivity, and weather protection and is ready to use. It has a whole lot of deployment advantages, and multiple applications to choose from by customers as per their needs, budgets and decorative requirements. Related: ACP Sheet – The Best Cladding Material For BuildingChange in composition of Aluminium Composite Panel with time

With time, the major changes in ACP happened in the composition of the aluminium panels. The overall thickness of the panels used is in the range of 3-6 mm(0.12-0.24in.). The width of the aluminium facings ranges between 0.2-0.8 mm.The core may belong to any of the three general categories:

- PE cores – these cores are made of 100% polyethylene(PE) and are flammable.

- FR cores – these cores are made up of a composite material containing 70%-90% of mineral wool/rock fiber/rock wool, which are non-combustible and act as a fire retardant.

- Aluminium forests – these are either made of the aluminium honeycomb structure or solid aluminium.

With different paints and coatings ACPs are also developed:

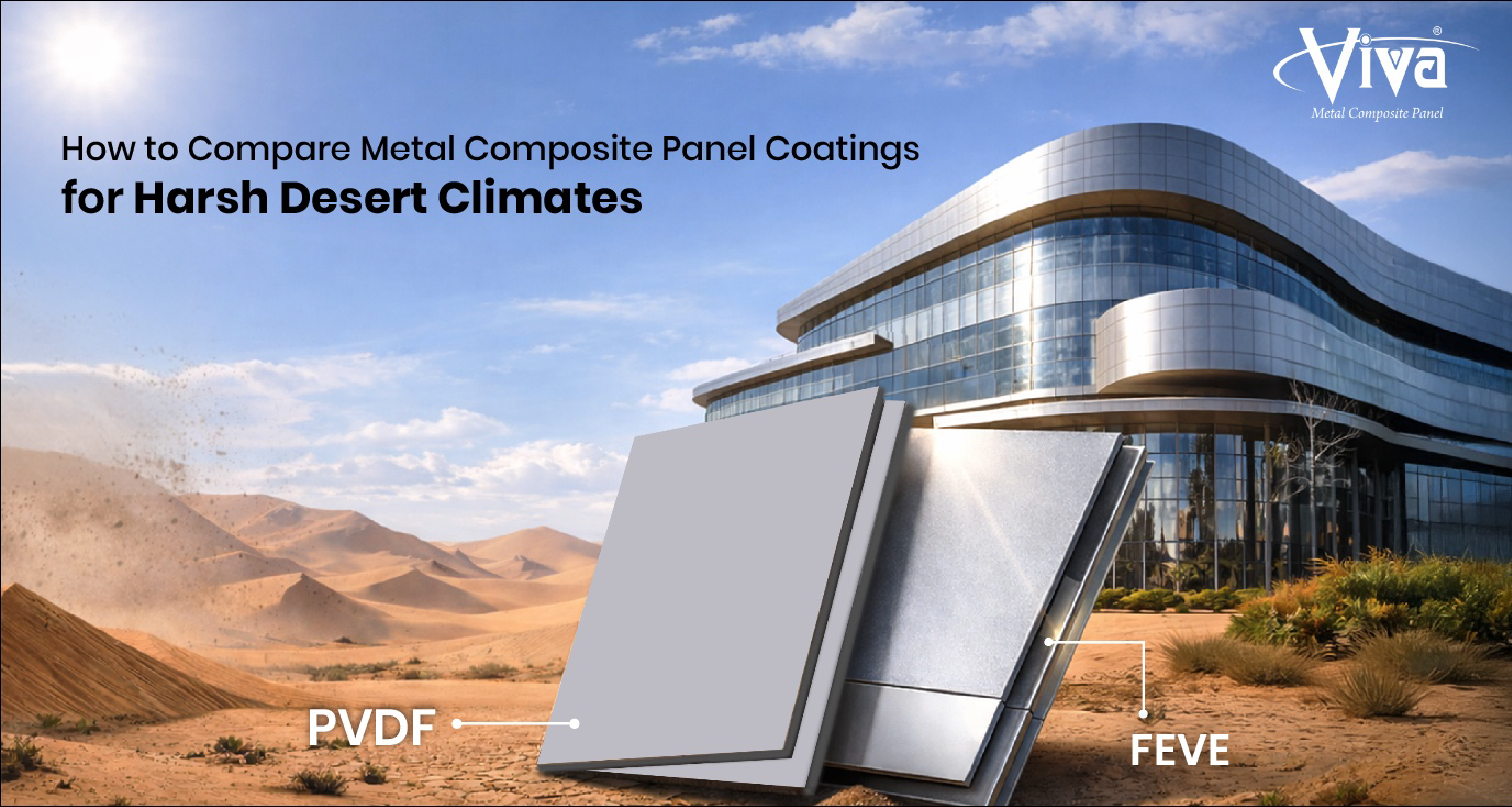

- PE/FR Constructional/Architectural Panel sheets coated with PVDF resin, (XT/ High Durable) polyester paint.

- Panel sheets coated with Nano PVDF

- Digital Printing/Signage Panel sheets coated with FEVE resin or high-quality polyester.

- Higher strength to weight ratio

- Lighter weight

- Material flexibility and adaptability

- Durability

- Superior insulation features

Evolution of its applications

Aluminium Composite Panel has come a long way from being used as a signage material in the past. Today, it finds applications in various projects and spaces, including; Internal Partitions, Building Renovations, Curved Fascias, Container Constructions, Internal Wall Coverings, Architectural Claddings, Machine Coverings and many more. ACPs are one of the most used materials that dominates the facade industry. Due to its light-weight features, it is the substance of choice for building temporary elements like trade show structures. Recently, it is being used as a backing material to mount fine-art photographs that are related to acrylic finish by making use of processes like face-mounting techniques.Aluminum Composite Panel is used to construct many famous architectural marvels. Some of them are:

- Spaceship Earth in Orlando (U.S)

- L’Oreal Paris building in France

- Guggenheim Museum Bilbao

- The Leipzig branch of the German National Library

- VanDusen Botanical Garden in Canada

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French