In the building curtain wall industry, two models of ACP sheet which are on the bandwagon are Aluminium Composite Panel (ACP Panel) & Aluminium Honeycomb Panel. Both sheets are visibly similar, yet the inner composition is different for both materials. Keeping this in mind, we have curated a few of the differential points between these two to make an informed choice while buying one.

Aluminium Honeycomb Panel

An aluminum honeycomb panel is a sandwich panel whose design is inspired by a natural hexagonal honeycomb. Its structure is designed in a way that upper and lower aluminum alloy is attached to an aluminum honeycomb core forming an I-beam.

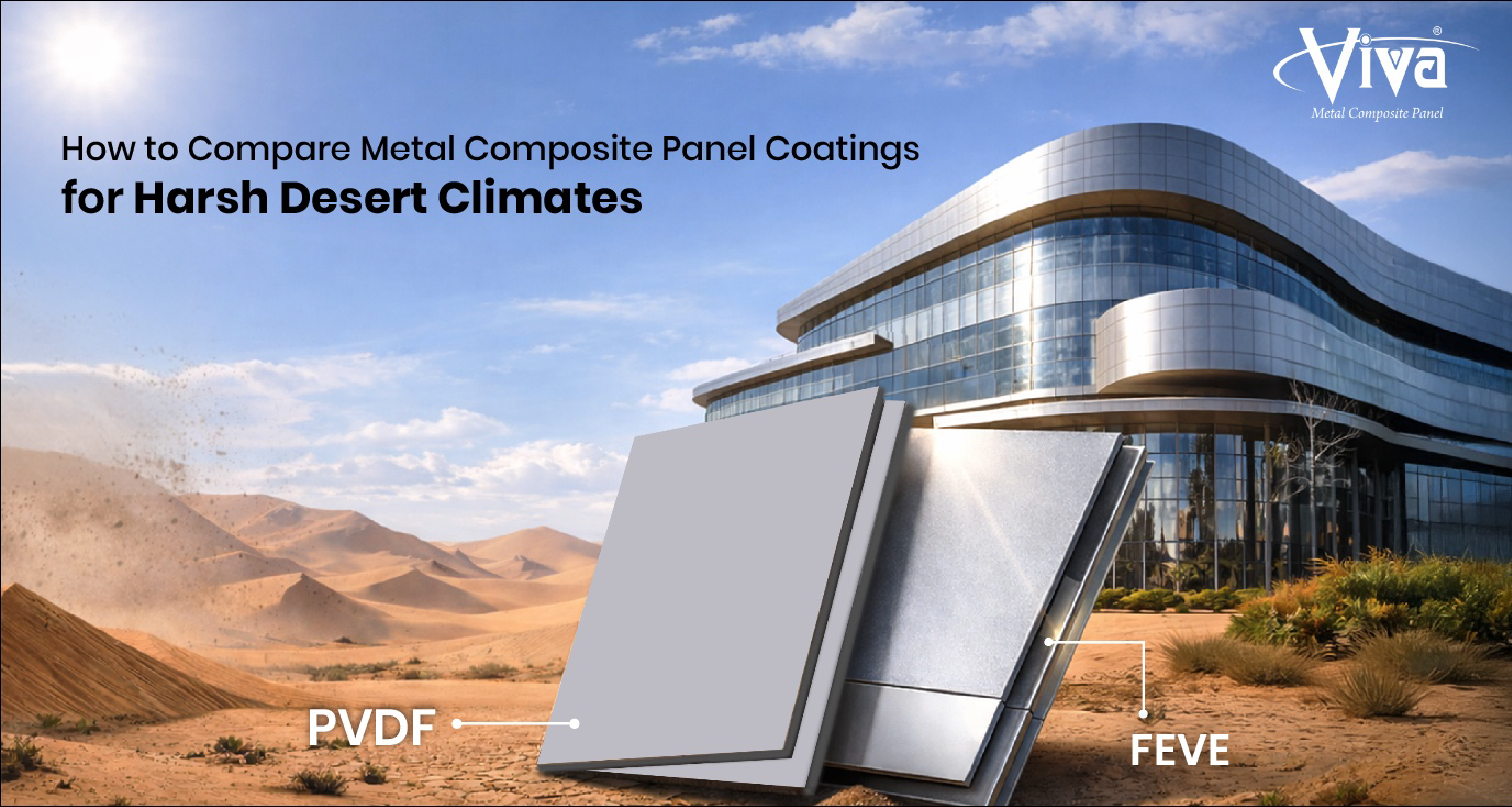

The honeycomb panel has polyvinylidene fluoride(PVDF) or fluoroethylene vinyl ether (FEVE). Fluorocarbon's rippling-free and self-cleaning properties are suitable for exterior panels, whilst polyester coating is more visible in interior wall panels.

Aluminum Composite Panel

Like Aluminium honeycomb panels, these are also sandwich panels. The structure of Aluminium Composite Panel or ACP panel is composed of two thin aluminum alloys pressed with a thermoplastic core, forming the shape of a sandwich, hence called sandwich panels.

You May Like: Aluminum Composite Panels – An Extra Layer Of Protection And Efficiency

Differences based on properties

Difference In Weight

Albeit both the panels are made of the same material but they exhibit a difference in weight. The design of the sheet is the reason behind the difference in their weight. The aluminum composite panel uses a layer of PE or LDPE which is made of plastic and available in 3mm to 8mm thickness, while honeycomb panels use a honeycomb core layer that is lighter than the plastic core and it is available in 12mm & 25mm. thickness.

Difference In Form Retention

The use of cladding material has recently changed with the evolution in structural design. Today the panels are shaped according to the design of the building structure. Aluminum honeycomb panels bring ingenuity to designs as it has better formability.

The panels are easier to shape in any design according to the needs. The sheets can be shaped in single-curved panels, double curved panels, or flat plates. These panels are also known for shape retention for a long time which helps in giving structural shape to many cladding designs.

Difference in Application

Aluminum composite panels are well known for their application in wall cladding, signage, and façade. The use of aluminum panels has also been included in the furniture industry as the sheets gel well with plywood or wood giving an opulent look to kitchen or bathroom cabinets.

Whilst, aluminum honeycomb panel is known for their application in aviation, aerospace, transportation, construction, military, and other areas. Because of its structural stability and low density, it is widely used for rocket fairings, car skins and doors, train bulkheads, and curtain walls for buildings.

Which Aluminum Wall Panel is Better?

After learning about the difference in material, structure and weight you already know the qualities of both sheets. Now, if you are wondering which one is better, then I would say both are better. Depending upon the needs and applications both are used. So, when you are buying an aluminum panel recognize your requirement and choose the ACP panel which suits best for you.

Viva is one of the leading names in the ACP panel industry. We have hundreds of designs and textures in aluminum panels. Our Aluminium Composite Panels and honeycomb panel are manufactured and tested in the Umbergoan factory. To know more about these panels get in touch with our experts, by mail at info@vivaacp.com

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French