In the dynamic world of architecture, ensuring fire safety has paramount importance. This brings us to the critical discussion of the myriad of choices you make during the construction process, and one of them is the selection of the right facade material for commercial and residential construction. The choices you need to make are between FR (Fire-Resistant) and Non-FR (Non-Fire-Resistant) grade panels. Understanding the differences between FR & Non-FR Panels can significantly enhance the safety of your construction. Let’s delve into what these are extensively.

FR Grade Panels

FR Panels, also known as Fire Retardant ACP Panels, are a class of construction material that is specifically designed to resist fire. A large percentage of inorganic minerals are used in the production of FR ACP panels, which offer a 2-hour delay in the spread of fire, giving people more time to evacuate and save lives. It doesn't release poisonous fumes that can make you suffocate or die. No smoke or droplets will appear on our FR panel during a fire.

Non-FR Grade Panels

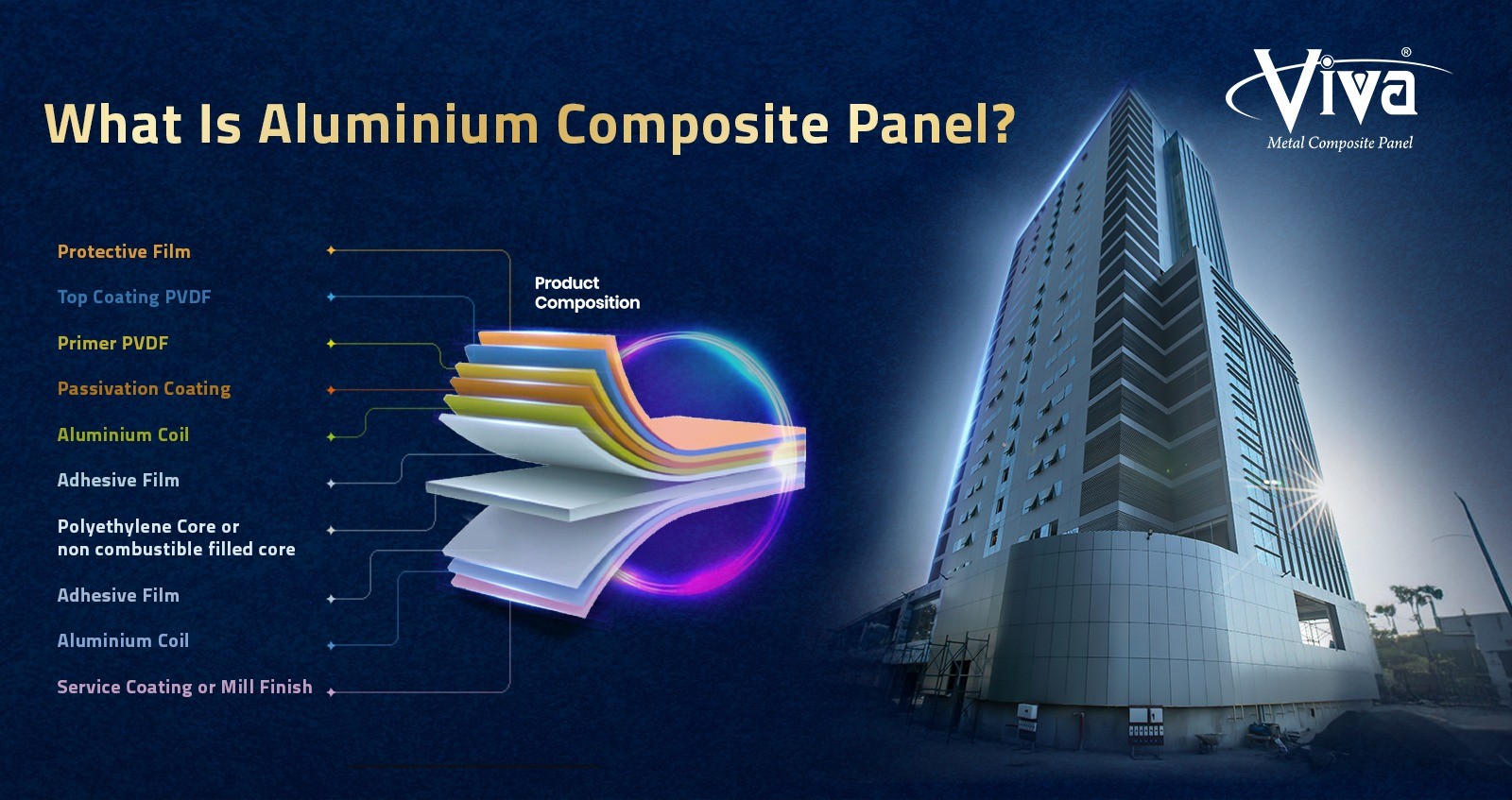

These are standard composite ACP panels that do not have any fire retardant feature. These materials are made up of two thin layers of aluminium coils sandwiched by a polymer core. Its polymer core is made of 100% virgin plastic or Linear Low-Density Polyethylene (LLDPE) and Low-Density Polyethylene (LDPE). These materials are low-density, flexible, and durable but flammable and may catch fire easily.

Virgin Plastic is the direct resin produced from a petrochemical feedstock, such as natural gas or crude oil, which has never been used or processed before.

Why FR Grade Panels are Important For Construction?

When it comes to facade perspective, you need to understand how a facade poses a threat to a building. In conversation with Mr Faizer Ali Dastagir, National Head-Projects of VIVA ACP has shared insight on how fire poses a threat to a building. The first is smoke, most people die of asphyxiation due to smoke when they are inside the building, the smoke produced due to the burning of the facade has toxic fumes that engulf the building. Another thing is the spreading of the fire within minutes. To protect the building, fire should not spread from one floor to another floor, also known as fire compatibilization. With Viva, we are mitigating these two factors with our range of Fire Retardant ACPs.

Walkthrough of VIVA ACP FR Grade Panels

When it comes to prioritising safety, Viva is at the forefront, with our range of FR-grade ACP panels we ensure your structure is well protected during the event of a fire hazard. Let’s understand how FR-grade panels from VIVA add a layer of safety.

FR A2+ Grade Aluminium Corrugated Composite Panel

We are the first manufacturer to bring an FR A2+ Corrugated Composite Panel, which consists of a honeycomb aluminium core. The panel consists of aluminium as the core, as well as the exterior sheet. As aluminium has a high melting point it makes the panel suitable to fight fire breakouts. We tested the panel at a temperature of 1960 degrees Celsius and put it under flame for over 2 hours. It didn’t produce molten droplets or toxic fumes. The panel stood the test for over 2 hours, making it

one of the safest fire Retardant ACP panels for resisting fire. Because there is no PE other than aluminium, aluminium core composite panels are completely fireproof and environmentally friendly. Additionally, there are different appearances regardless of whether stone, wood, or mirror processing was used.

FR Class B1 & FR Class A2 Panels

FR B1

FR Class B1 comprises 70% mineral and 30%. The mineral core is made of Magnesium Hydroxide and Aluminium TriHydroxide which are halogen-free and inorganic. Class B1 will not release lethal poisonous gases. Smoke is a terrible mixture of CO and CO2, and is to blame for 75% of deaths in fire accidents.

Unlike other fire-prone materials, it won't produce a lot of heat and won't contribute to the spread of flames to the building's upper floors for at least two hours. Instead of melting into blazing droplets, these panels transform into ash.

FR A2

FR Class A2 is made with 90% mineral and 10% polyethene recycled core. It can efficiently safeguard high-rise structures that are more than 20 meters. It produces a negligible amount of heat and has no effect on how quickly a flame spreads. No poisonous fumes, smoke, or flame droplets are produced, ensuring minimal property damage, easy escape, and no possibility of casualties.

Choosing FR Class A2, FR B1, and A2+ Panels helps to retard the penetration of the flame, which helps in flame compartmentalisation, as mentioned by Mr Faizer Ali Dastagir. When you are choosing FR-grade panels, you are not only choosing to protect the building from fire penetration but also safeguarding it from toxic fumes that lead to most deaths during fire accidents. Here are some of the benefits that you would receive with a fire retardant panel sheet. The 4mm FR B1, and FR Class A2 panel has a 5.53W/m²K heat transmission coefficient tested at ASTM C 1363, and has a fire classification of EN 13501-1, with fire rating DIN 4102.

Advantages of Facading With FR-Grade Panels

Defying Flames

FR panels of VIVA ACP are fire retardant, which translates the panels into defying the flames. The fire retardant ACP consists of the mineral & aluminium core of the panels engineered to resist high temperatures, which makes it suitable for areas where fire safety is paramount such as high-rise buildings, hospitals, and public facilities.

Legal and Regulatory Compliance

Building codes and regulations vary from one location to another when it comes to fire-resistant material in specific applications. By opting for fire retardant ACP panels, architects and builders of a construction project can ensure the project complies with these safety standards. Today, with the surge in high-rise buildings in urban localities, compliance is not just a formality, rather it is a commitment to the safety of your building’s occupants.

Extends Evacuation Time

In times of unfortunate events of fire, every second matters. FR grade panels of VIVA ACP are manufactured to allow down fire for up to 120 minutes, which provides occupants with valuable extra time to evacuate safely. The additional time can be the difference between life and death in an emergency.

Property Protection

Fire is a threat to both life and property, FR grade panels can also protect and lower the damages to a property. The panels help to maintain the structural integrity of your building during a fire, potentially reducing repair and replacement costs. This adds resilience to the property which can safeguard valuable assets inside the structure.

You May Also Like: Fire Retardant ACP Sheets: The Need Of The Hour

Conclusion

The main difference between fire-rated VIVA ACP and non-fire-rated VIVA ACP sheets is different core materials i.e. Mineral core and Polymer core. The mineral core is made up of about 70% inorganic materials such as Aluminium Trioxide and Magnesium Hydroxide and 30% polymer and the polymer core is made up of about 100% virgin plastic or recycled material such as LLDPE & LDPE.

The choice between FR and Non-FR is clear here. To prioritise safety, especially in high occupancy areas having a fire retardant ACP facade is essential. We have Thomas Bell Wright certified, it is a Dubai-based multi-accredited firm that has over 25 years of expertise in the industry and offers the highest level of fire safety certification to curtain walls based on their testing, and quality inspection. Other than that, Viva’s fire retardant panel sheet complies with ASTM D 1929, NFPA 285 and ASTM E 84.

The level of fire resistance depends on the panel’s composition, thickness and the fire rating it carries. At Viva, we are committed to providing aesthetics, builders, and project managers with top-tier FR Panel solutions that enhance safety without compromising on aesthetics or functionality. Know your building fire safety before purchasing the products as the decision can make all the difference in the world.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French