The components and materials we use in our construction are perhaps the essential aspects of the project. Some people choose low-cost, low-quality construction materials, while others seek the highest possible quality. Aluminium composite panel is one of the construction materials that has evolved to provide high-quality attributes at Reasonable rates (ACP). The core, coating material, protective films, and colour protection are all structural properties of ACP panels, however, the core of an ACP sheet is an essential element of all.

The structure of an Aluminum Composite Panel is made of three layers that, when combined with a PE coating, make an insulated flat panel. The two layers of aluminium sheets are firmly bonded together with a polyethylene internal core, which, when coated with PE, makes the surface flat and robust. Although PE has proven to be effective, there is an increase in fire behavior and paint fading difficulties with PE core and coating recently. The problem with PE cores and coats is that they can swiftly spread fire in the event of a disaster, and lose colour quickly owing to exposure to direct sunlight and other adverse weather conditions.

Disadvantages of PE Coating:

- PE coating is frequently affected by UV degradation, making it unsuitable for high altitudes and building exteriors.

- PE coat has a limited application in high temperatures due to chain degradation, which can result in oxidisation. This results in cracks, paint peeling off, and fades in the ACP sheets.

- Polypropylene (PE) has poor bonding qualities, making it difficult to paint.

- PE is highly flammable and melts when exposed to heat.

This is why major manufacturers, such as VIVA, offer solutions to prevent future paint fading and fire problems. We're coming up with new ways to improve ACP sheets.

You May Like: 5 Chic And Unique ACP Cladding Designs For Modern Home

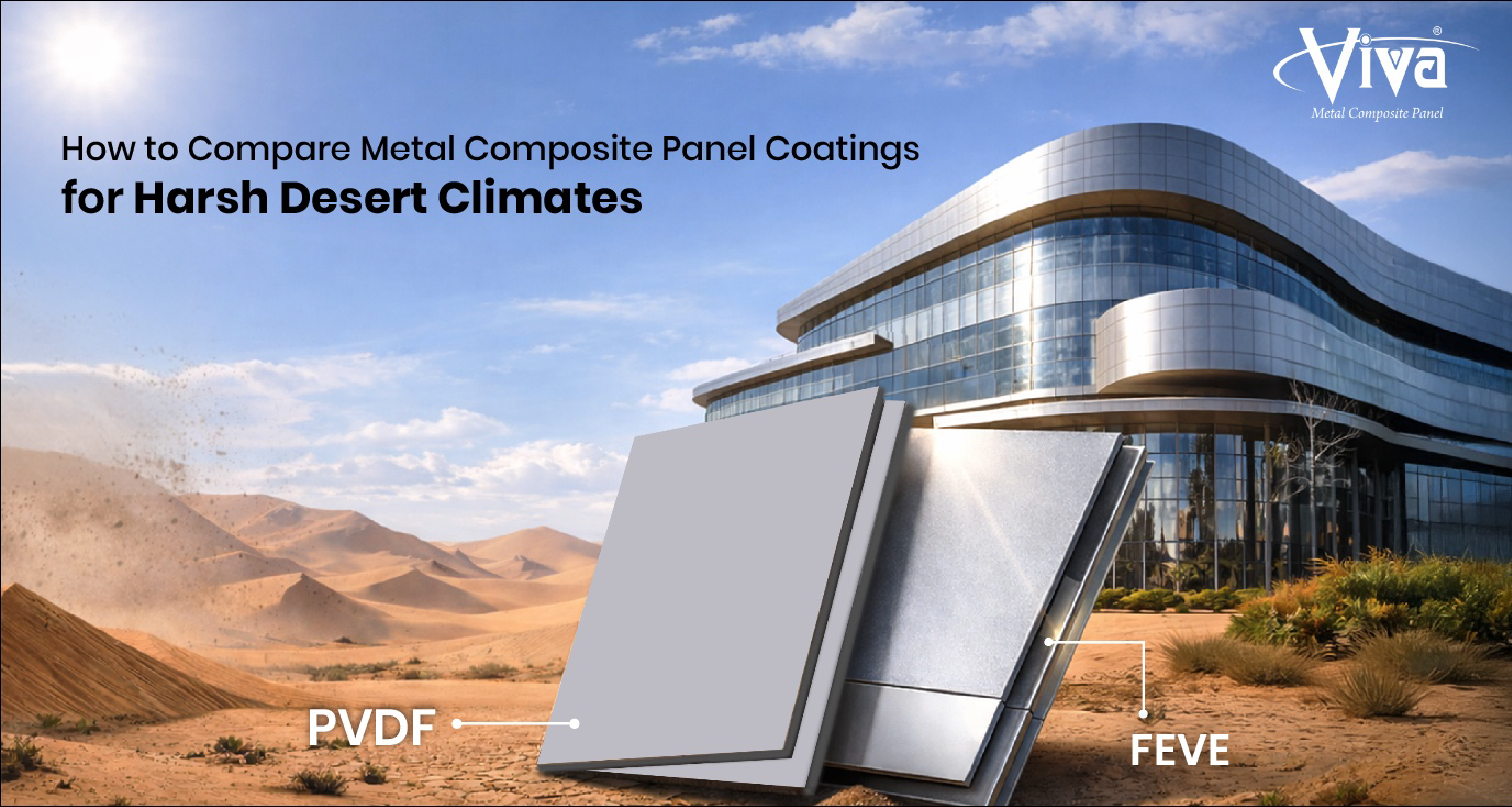

PVDF coating components have taken the position of PE coating materials, which are significantly superior to PE elements. PVDF coated ACP panels are the highest-quality form of exterior cladding. The usage of fluorocarbon molecules, one of the strongest chemical compounds, is the key to high adherence to the PVDF coat. PVDF ACP panels can also be painted in a variety of ways. Certain colours from the RAL palette are no longer usable due to the usage of UV-resistant pigments in the paint material's formula. However, multilayer coat application technology enables high-precision imitation of materials such as silver, gold, copper, etc. These panels are practically fade-free and offer a higher resilience to mechanical damage and corrosion. The material is chemically resistant and performs well at temperatures up to 120 degrees Celsius. The application of PVDF coatings protects the building's facade from the corrosive effects of air even with high salt content in a marine climate.

PVDF aluminium composite panel has a Polyvinylidene Fluoride (PVDF, 70% content) surface that is weather-resistant, impact-resistant, UV resistant, sound and heat resistant, as well as colourful, smooth, and attractive. It has a 20-year lifespan and is primarily used for exterior design. The PE-coated ACP sheet, on the other hand, has a 10-year life expectancy and can be utilized for interior design and advertisement boards.

We at VIVA use 70% KYNAR 500 certified PVDF (fluorinated polyvinyl) paint that meets ASTM and EN (European Nation) standards. Arkema Inc. has a registered trademark for KYNAR 500. Our paints are devoid of lead. For external applications, we use FEVE (Lumiflon) based paint and polyester/PET film for textured interior architecture surfaces. PVDF contains anti-ageing characteristics, whilst FEVE is utilised to create a high-gloss finish. To suit your architectural needs, VIVA can modify the aluminium composite panel or ACP Sheets to wood, marble, mirror, or any other customised texture. VIVA's ACP sheets have high-quality coatings that require less maintenance, lowering your maintenance expenditures. Both coatings can make the ACP board durable and pollution-resistant.

To know more about PVDF/FEVE coating that we use, click here or drop us an email at info@vivaacp.com.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French