Price increases are being implemented in the ACP sector in India as a result of rising raw material costs. The ACP Manufacturer Association has stated that the costs of various types of composite panels, made from a mix of metal and plastic composites, would be increased by 7-10 percent. The vast majority of players have said that they would raise their rates with effect from September 1, 2021. They addressed the industry's current problems, such as the increase in raw material costs and the control of debtors' default.

Members of the ACP Manufacturers Association have chosen to raise the prices of their goods due to the rise in the prices of raw materials such as Aluminium Coil, Polyethylene Granules, Polymer Films, and Transportation Expenses in increased ACP price.

You May Like: Factors That Affect the ACP Sheet Price

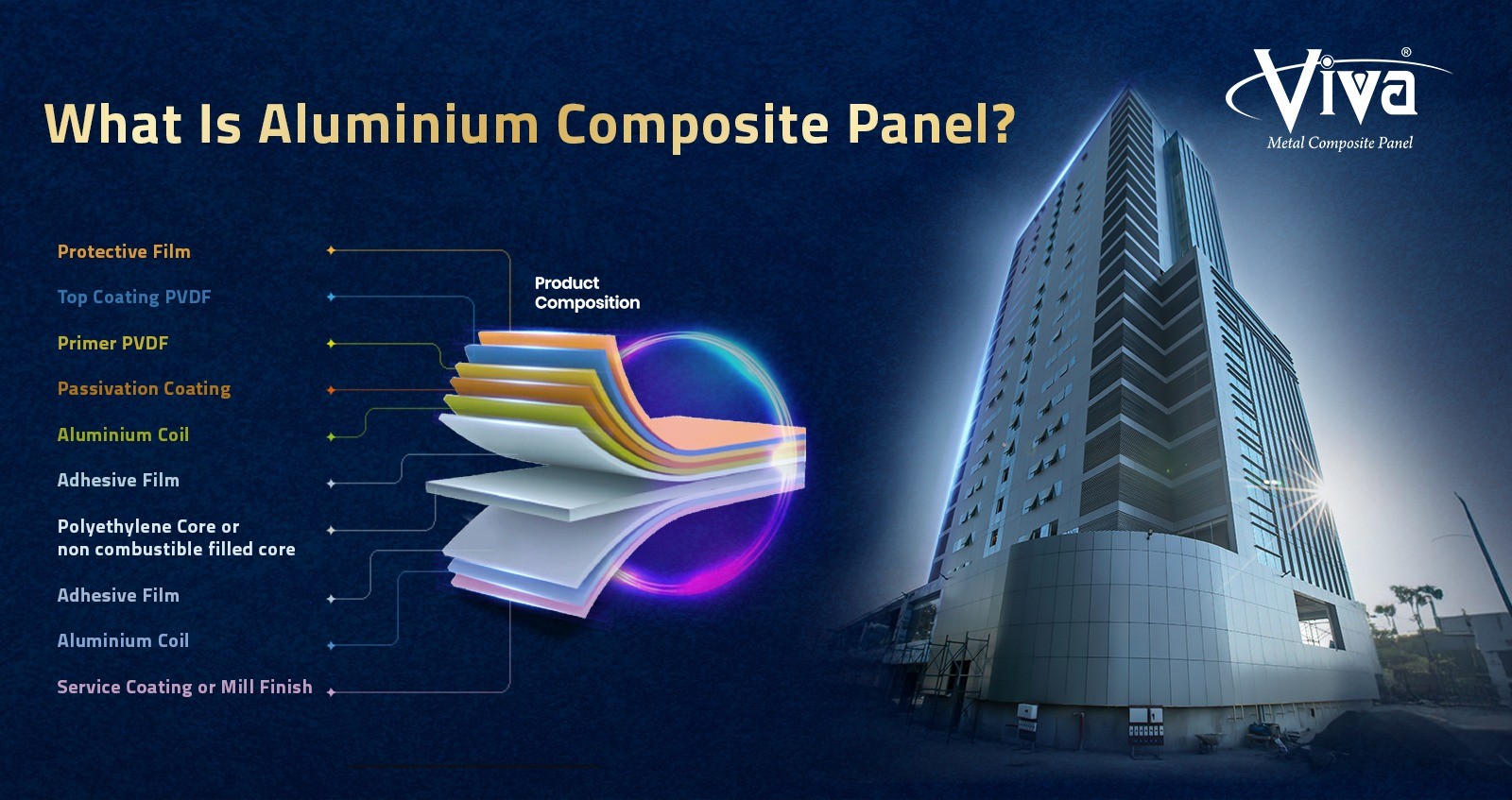

Aluminium Coil is the primary raw material used in Aluminium Composite Panels, which are often found in the facade and signage industries. The number of aluminium composite panel manufacturers in India has increased significantly, particularly in the past five years, due to increased demand in a variety of industries. ACP manufacturing firms, Viva, have been severely harmed by sharply rising costs, affecting ACP production and supply in the market.

According to the majority of industries in the ACP sector in India, ACP is mostly imported from one source nation, namely China. Viva has sourced only from India, this means they do not have to spend on logistics. This translates to lower prices for the end consumer.

The situation in the ACP manufacturing sector is almost identical to that which exists in the Melamine and other decorative and panel businesses. Despite the sharp price increase, raw materials are not readily accessible on the market in sufficient quantities to meet the growing demand, and Viva is doing everything possible to keep the ACP price affordable.

In general, aluminium alloy and polyethylene polymers are the primary raw materials used in the production of ACP panels. Even if various kinds of aluminium alloys have the same thickness, ACP prices are not the same; nevertheless, even if they are the same type of material, the thickness will impact the price fluctuation to a certain degree.

Second, the variation in composite materials used on the surface of ACP panels results in a range of costs for the same product. Fluorocarbon film, roller coating, and so forth. The higher the quality of the surface decorating material, the higher the cost of the material. Using a high-quality polymer binder in the intermediate composite glue will also increase the cost of producing the aluminium composite panel, as would the use of a high-quality polymer binder. In the ACP panel construction industry, there is no such thing as a fixed ACP price.

The core processes in the ACP panel industry are not performed without thought and logic; instead, they are based on a complex mathematical formula of ACP sheet price and fitting. Perhaps there is a small variation between each manufacturer, but the total difference is not significant. Raw materials are the most significant element in determining price fluctuations, and Viva is still trying to fight the price increase to make it more affordable to customers. Viva ACP is Made In India Product which means there is a lot of cost-saving in all processes that go into making ACP by virtue of lower material costs, lower labour costs, and economies of scale that only big players like Viva can enjoy.

One of Viva's main objectives is to provide new products reasonably priced to its customers. They are always developing architectural landmarks that will empower consumers as they benefit from the fantastic variety of ACPs available to them. Since its inception, they have been producing a wide range of products ranging from solid to marble to various others at an affordable ACP price.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French