When it comes to architectural design, few materials offer the versatility, durability, and aesthetic appeal quite like Aluminium Composite Panels (ACPs). Often celebrated for their sleek appearance and structural integrity, ACPs are a staple in modern construction. But what exactly makes them so robust? The answer lies in the intricate composition of their layers, each playing a crucial role in forming a bond that withstands the test of time. In this exploration at Viva ACP, we delve into the anatomy of Aluminum Composite Panels to uncover the love in every layer.

Layer 1: The Core

At the heart of ACP lies its core, typically composed of a non-toxic polyethylene (PE) or fire-resistant mineral core. The core is the foundation of the panels providing structural support, adding strength and stability to the aluminium composite panel. Much like the foundation of a strong relationship, the core of ACP forms the basis upon which the rest of the panel is built. The core of the panel ensures it remains steadfast in the face of external pressures, such as wind, rain and impact.

Layer 2: Adhesive Film- The Bonding Agent

Encasing the core are two thin layers of aluminium alloy bonded together with the bonding agent the adhesive film. At Viva, we use Dupont adhesive film for bonding the sheet together. Dupont is known to be one of the finest adhesive film manufacturers. The adhesive film is made of high grade non-toxic polymer and it not only binds the aluminium layers to the core but also facilitates the transmission of loads between them. Just like trust and communication is important for any relationship, the adhesive film builds a connection that allows for mutual support and resilience, and makes the ACP sheet strong enough to withstand high impact.

Layer 3: The Aluminium Coil

One of the most integral parts of the composition of aluminium composite panels is Aluminium Coil. At Viva, we use aluminium coil alloy 3003/3105/5005. The alloy contains magnesium that adds strength and ductility for better workability with the panel. Aluminium coil makes the panel highly flexible, as it is a malleable metal and can be used for a range of applications. The coil provides backbone and strength to the panel, ensuring its ability to withstand environmental factors such as wind loads, temperature fluctuations and impact resistance. The aluminium coil layer just like in any relation strengthens the base of the bond. It ensures corrosion resistance of the panel, adds durability and 90-degree bendability of the panels.

Layer 4: The Passivation Coating- The Protecting Layer

As aluminium oxides when coming in contact with oxygen in the air, it is important to create a physical barrier that does not allow oxygen to oxygen from the environment to enter and settle on the sheets of aluminium. This process is called passivation coating, creating a shield layer on the sheets to protect the panel from corrosion.

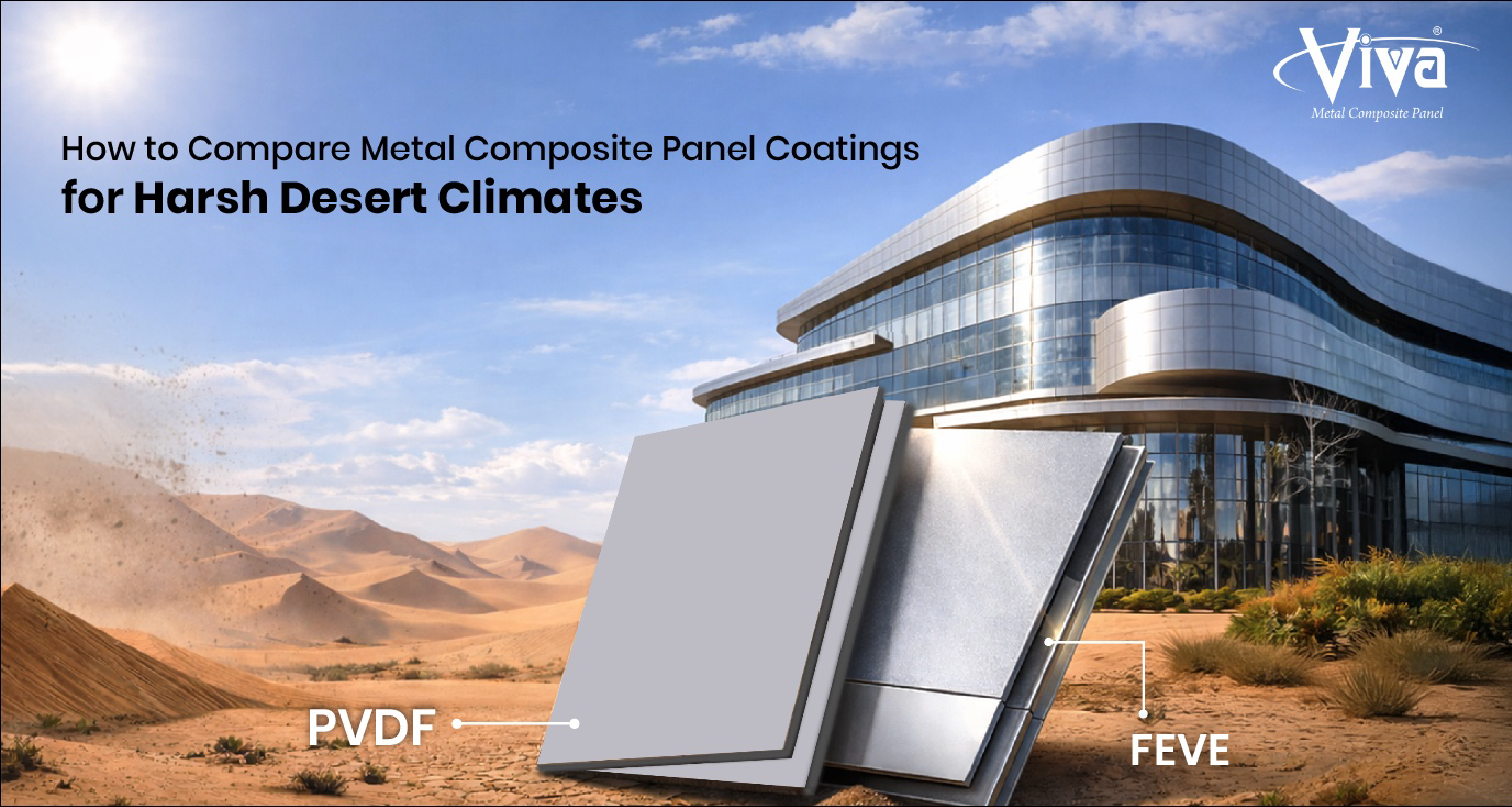

Layer 5: Primer PVDF

The shine of architectural facade panels comes with the right shade and colour. And for this, it is important to add primer PVDF as a protective coating on the panel. Before the application of PVDF coating, the primer is added to enhance adhesion and ensure uniform coverage. The additional step reinforces the bond between the coating and the substrate, fortifying the panel’s protective qualities and extending its lifespan.

You May Like: Discover The Fascinating Process of Creating Aluminium Composite Panel: An Inside Look

Layer 6: The PVDF Coating

PVDF is a polyvinylidene fluoride paint, it is a high-performance coating. PVDF paint is added to make the panels vibrant, colour, add texture, and create uniqueness in the panels. Apart from adding aesthetic qualities, PVDF is renowned for its exceptional weather resistant and durability. This layer shields the panel from the elements, resisting fading, chalking, and corrosion over time. Its longevity mirrors the endurance of enduring love, withstanding the trials of time and environment.

Layer 7: The Protective Coating

Finally, the outermost layer of an ACP is coated with a protective finish, typically comprising a fluoropolymer resin or polyester paint. This coating serves as a shield against environmental factors such as UV radiation, moisture, and pollutants, preserving the panel’s appearance and structural integrity over time. Much like acts of kindness and understanding, the protective coating safeguards the ACP against the wear and tear of everyday life, ensuring its longevity and beauty endure.

Love In Every Layer of ACP Sheet

The strength of an Aluminium Composite Panel lies not only in the quality of its individual layers but also in their unified purpose. Just as a relationship thrives when partners work together towards a common goal, the layers of an ACP complement each other to create a product that is greater than the sum of its parts. It is this synergy that imbues ACPs with their remarkable durability and versatility, making them a trusted choice in architectural design worldwide.

Experience the excellence of ACP sheets with Viva ACP, where innovation meets quality. Explore our product range at https://vivaacp.com/

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French