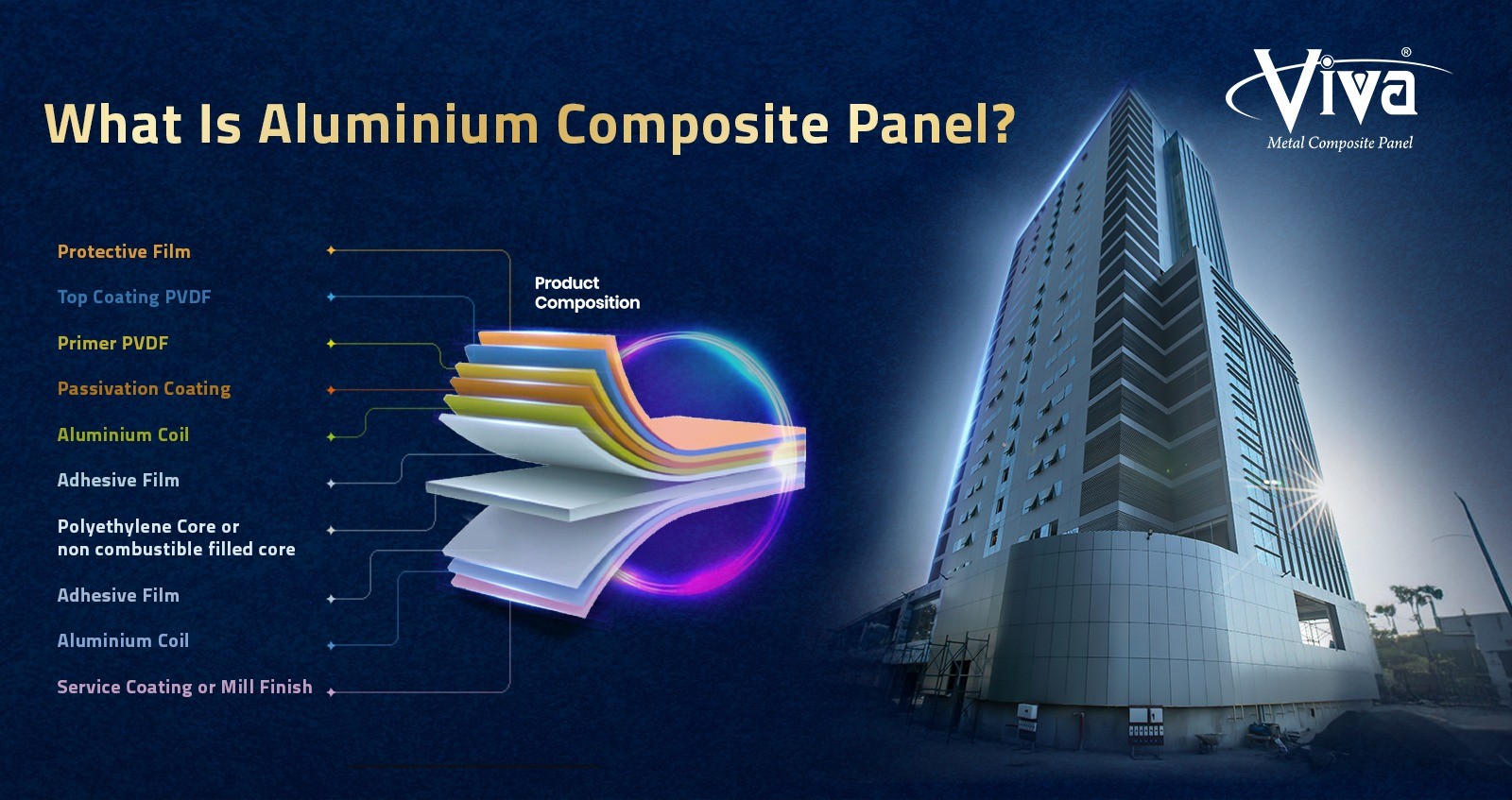

Aluminium Composite Panel (ACP) has gained popularity as a cladding material over the years due to its numerous advantages and versatility. Comprising thin sheets of Aluminium alloy, these panels are compressed with a core made of LDPE material. Despite their lightweight nature, these sheets exhibit remarkable strength, allowing them to withstand impact and external forces effectively. So, if you are an architect, or builder heading toward planning a project where the choice of cladding material is ACP sheets, you must understand the ACP thickness and its application in the interior and exterior. In this comprehensive guide, we will discuss the panel thickness range of Viva ACP and provide the recommendations for its best application.

Understanding the Importance of ACP Thickness

The thickness of ACP sheets is vital in determining the performance and suitability of different applications. ACP thickness affects weather resistance, durability, aesthetics, overall structural integrity and ACP sheet price. It is crucial to select the appropriate thickness to ensure the longevity and functionality of your cladding system.

The Versatility of ACP Sheet Sizes Thickness Range

3mm ACP Sheets:

0.25 Aluminium coil thickness. This panel is ideal for interior applications. These are lightweight panels and can be easily cut, shaped, and bent allowing customised designs along with helping in easy installation.

4mm ACP Sheets:

4MM ACP Sheets are available in 0.25 /0.30/0.05 coil thickness. In this, the application is based on the two variants:

4MM– 0.25 & 0.30 coil thickness, they are used in Villas, Bungalows, 3-5 Floor Small Buildings.

4MM– 0.5 aluminium alloy coil thickness, they are been used in high rise buildings like commercial, residential, Airport.

6MM ACP Sheets:

6MM is typically used for exterior applications, and these are the alternative to Solid Aluminium Panel. These panels are suitable for heavy-duty applications that require exceptional structural integrity. These panels are mostly used for cladding high-rise buildings.

Honeycomb Panels

Honeycomb panels are new-age cladding material that consists of a honeycomb structured core, which is inspired by honeybees. These panels have high impact resistance, as the structure of the core gives a cushioning effect, hence elevating its structural strength. Moreover, these panels are thermal insulated and sound insulated which is why these are mostly used in Research Centers, Defence Centers, Auditoriums and Data Centers. Honeycomb panels are available in various thicknesses each having unique properties hence the application differs based on the thickness of the panels.

Honeycomb Panel Thickness:

12MM- These panels are mostly used for interior application.

25MM- These panels are used for exterior applications.

Factors To Consider When Selecting ACP Thickness

Several factors should be taken into account when determining the ideal ACP thickness for your project. These factors include the location of the cladding, exposure to weather elements, building height, expected lifespan, and budget constraints. Let’s delve deeper into these considerations to help you make an informed decision.

Location of the Cladding

The location of the cladding plays a key role in determining the right ACP Sheet size for any space. The interior and exterior have differences in the environment that the facade deals with. The exterior facade is exposed to harsh weather conditions such as rain, wind, and UV radiation. Therefore, thicker ACP sheets are recommended to ensure better weather resistance and protection from environmental factors. While, interior cladding is generally shielded from direct weather exposure, allowing for the use of thinner ACP sheets.

The location of the cladding is an influential factor. As mentioned earlier, 3mm is ideal for the interior and in honeycomb panels, 12mm is the preferred choice for interiors, while for exteriors 4mm ACP sheet, 6mm, and 25mm honeycomb panels are preferred.

Exposure to the Weather Elements

The level of exposure to weather elements should be taken into consideration when selecting ACP sheet thickness for exterior cladding. If the building in an area receives heavy rainfall, or extreme heat/cold waves, thicker ACP panels should be the choice of the architects. The reason is the ability to resist extremities in the changing environment. These sheets provide better insulation and protect the building from moisture infiltration and thermal expansion.

Building Height

The height of a building is a relevant factor in determining the ACP sheet sizes. Tall buildings are more susceptible to wind pressure, which can exert substantial force on the cladding system. As mentioned above in the blog, ACP sheet thickness of 4MM with 0.5mm aluminium alloy coil is usually used for spaces with high wind pressure. Other than that, 6mm ACP is also used for rise high construction.

4MM vs 6MM: Which One is Better for High Rise Construction?

While extending into our discussion ACP sheet for high rise construction, mostly 4mm and 6mm ACP sheets are used. But which one is better?

Well the difference in 4mm and 6mm ACP sheet lies in the core. The 6mm ACP sheet’s core is similar to solid aluminium panel which adds exceptional structural integrity, in comparison to 4mm ACP sheet. Although, as 6mm ACP thicker core, the weight of the panel is a restraining factor when installed in high rise as additional safety measures need to be taken. Whereas, 4mm has ease of installation in high-rise. Moreover, 4mm ACP is flexible, and with CNC tools it can be programmed to cut into specific designs with ease.

Hence, we can conclude that, 4mm ACP sheet is better choice for high rise construction, while 6mm is useful for bungalows or urban housings.

Also Read: Why ACP Sheets Are Available In Various Thicknesses And Sizes?

Conclusion

In the realm of facade and cladding, the sizes and thickness of panels matters. From ease of handling, installation and ability to add structural support it all comes down to the right choice of the material. With our exceptional flatness in the sheet and commitment to quality, we continue to elevate structural with visually aesthetic appeal.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French