When choosing materials for exterior applications, durability is a primary consideration. These materials endure humidity, dust, UV exposure, salt-laden winds, fumes from vehicles, industrial gases, and the simple passage of time. Professionals often go for Aluminium Composite Panels (ACP) or Zinc Composite Panels (ZCP) for coastal, urban, and industrial applications.

When comparing ACP vs ZCP, the major question is how these materials stand up against these forces year after year. Each material brings its own strengths and its own quirks. In this article, we will discuss how these materials age in different areas, like coastal, urban and industrial zones:

Understanding ACP & ZCP

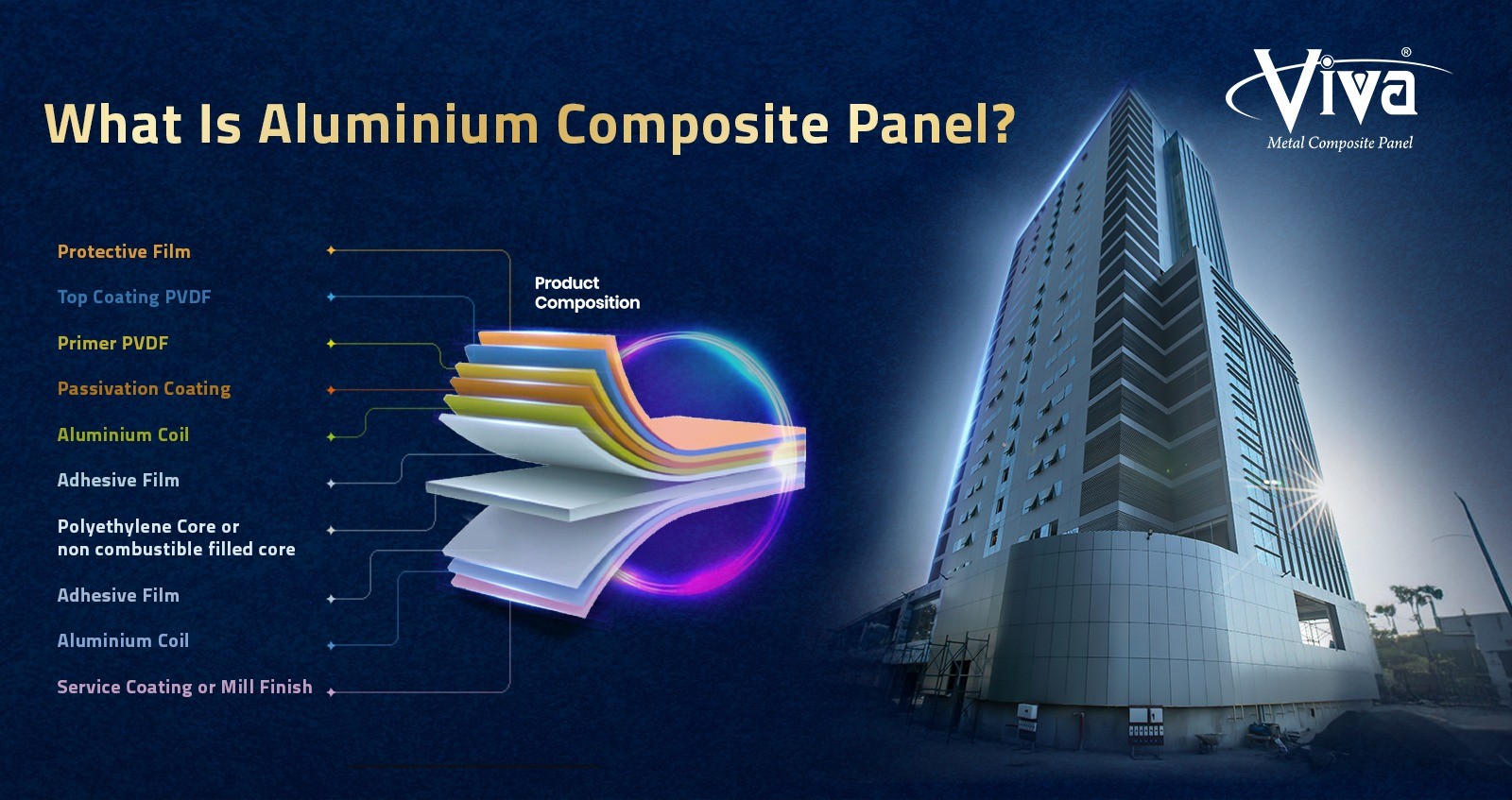

Aluminium Composite Panels (ACP) are made by sandwiching two aluminium sheets with a core, usually made of polyethylene. Since aluminium itself is a reactive metal, it comes with a protective coating that acts like a barrier between the panel and the environment. At Viva ACP, we use good-quality coatings like PVDF or FEVE that shield the ACP sheets from UV rays, salt, industrial chemicals, and pollution. As long as this protective layer stays intact, the panel ages slowly and predictably.

Zinc Composite Panels (ZCP) behave differently because zinc interacts directly with the atmosphere. Instead of depending on a coating for protection, zinc protects itself by forming a patina, a thin surface layer created through natural chemical reactions with air and moisture. This patina changes the colour and texture of the panel over time, shifting from bright to a more muted, matte finish. The patina works as a self-sealing layer, helping the metal last for decades, but it also means that the surface appearance continues to evolve in a visible way.

Here’s a quick overview of ACP vs ZCP:

| Feature / Behaviour | ACP (Aluminium Composite Panel) | ZCP (Zinc Composite Panel) |

|---|---|---|

| Base Metal | Aluminium alloy | Zinc |

| Coating | PVDF / FEVE coatings for UV, corrosion resistance | Usually comes with protective coatings; zinc naturally forms a patina |

| Corrosion Resistance | High, especially with PVDF coatings | Moderate to high; zinc resists corrosion through patina formation |

| Aging Behaviour | Retains colour well; minimal surface change if coating is intact | Surface darkens/weathering occurs as patina develops |

| Maintenance | Low; occasional cleaning | Moderate; patina is natural but pollutants may cause uneven weathering |

| Expected Lifespan | 15–25+ years depending on grade & coating | 30–50+ years depending on exposure and maintenance |

| Fire Behaviour | FR ACP options available (A2 grade) as per EN standards | Zinc itself is non-combustible |

| Weight | Lightweight | Heavier than aluminium |

| Cost | Generally affordable | Higher material cost |

| Best For | Coastal, urban, and industrial zones with good coating selection | Urban and dry industrial zones where natural ageing is acceptable |

Aging of ACP & ZCP

The ageing of the metal composite panels varies depending on where they are being used. Let’s take a look:

How ACP Ages Across Zones

As we mentioned previously, ACP ages primarily through the behaviour of its coating. High-quality coatings act like a shield that protects the aluminium skin from UV rays, pollutants, and moisture.

In coastal regions,

ACP is a great choice for installing a facade. While the salt in the air can be harsh on exposed metals, coated aluminium doesn't corrode. A good-quality PVDF layer, in fact:

●Reduces the impact of salt spray,

●Prevents chalking, and

●Slows down colour fading.

Over time, ACP tends to retain its original shade with only mild dulling in extremely aggressive coastal environments.

In urban environments,

The aging of ACP is very slow. Since the panels are exposed to dust, vehicular emissions, and sunlight, the coating can easily offer protection against these elements. Hence, their finish looks as good as new with minimal maintenance for many years. Plus, with Viva ACP’s NANO topcoats, our aluminium composite panels help reduce the buildup of grime, so the façade keeps its clarity with relatively light upkeep.

Industrial areas

Causes a different kind of stress to the panels. Chemical fumes, particulates, and industrial gases can settle on surfaces and gradually affect the material. ACP with high-performance coatings withstands these conditions well. Fire-retardant ACP panels, especially those certified to A2 standards, also help firms meet safety requirements in these zones. The panels may show mild chalking after persistent exposure to harsh chemicals, but the aluminium remains structurally sound over time.

How ZCP Ages Across Zones

Zinc is a moderately reactive metal and reacts with the atmosphere. The metal ages differently in different environments:

In coastal settings,

The high humidity and salt-laden air caused ZCP to form a patina more quickly. The change often starts unevenly, with areas exposed to more moisture developing patina faster than shaded regions. Even though the panels stay strong, the aging process is more noticeable than with ACP, especially during the first few years.

Urban environments

Leads to steady and predictable patina formation. Pollutants from vehicular traffic and general moisture in the air contribute to a uniform, matte surface over time. The panels transition gradually, and the surface tone becomes consistent after a certain period, making ageing easier to anticipate.

Industrial zones,

Accelerate the reactions that zinc undergoes. Airborne chemicals, especially sulphur compounds, can deepen the patina faster. The surface may darken more quickly in such environments, creating a visual shift that is more pronounced than what ACP typically displays.

Final Thoughts

We can safely say that there is no single, universal answer to which material ages “better.” In coastal zones, ACP provides a more stable appearance, while ZCP offers long-term durability with more visible weathering. In urban environments, both materials perform well though ACP maintains its original look for longer, and ZCP ages steadily with its natural patina. In industrial areas, ACP shows greater resistance to pollutant-induced changes, whereas ZCP continues to function structurally even as the surface undergoes noticeable transformation. So, choosing between ACP vs ZCP should not depend on which material is superior overall, but on which one responds best to the conditions of your site and the visual expectations of your project.

FAQs

Q.1. Which material handles pollution and soot better?

ACP performs very well in polluted urban corridors because its coatings prevent soot absorption and reduce surface dullness. ZCP will also endure the environment, but its patina will react with pollutants, gradually altering the surface tone. If you prioritize appearance, ACP is better in this situation.

Q.2. Our industrial facility releases mild sulphur fumes. Will ACP or ZCP age more gracefully?

ACP is generally better at resisting chemical fumes because its protective coatings block pollutant reactions. ZCP, on the other hand, will form a darker patina more quickly in sulphur-rich air, resulting in noticeable surface ageing.

Q.3. What do you recommend is a better façade material that won’t look old too quickly?

ACP is the safer recommendation if the client prioritises a “new look” that lasts. Its coating slows down aging and preserves the panel’s original colour for many years. ZCP, while durable, naturally evolves in appearance and therefore shows ageing more noticeably.

Q.4. Does choosing FR-grade ACP make a difference in ageing?

FR (especially A2-grade) ACP not only improves fire performance but also typically comes with high-quality coatings that enhance durability. So yes, an FR-grade ACP often ages better because it is engineered for tougher conditions overall.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French