23-Feb-2026

Recent Blog

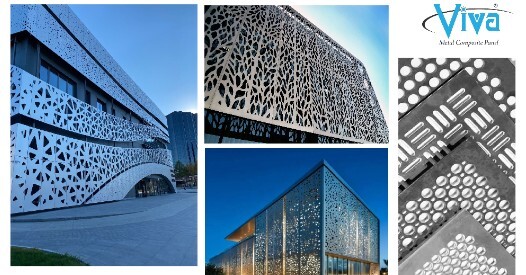

Innovate with Viva ACP

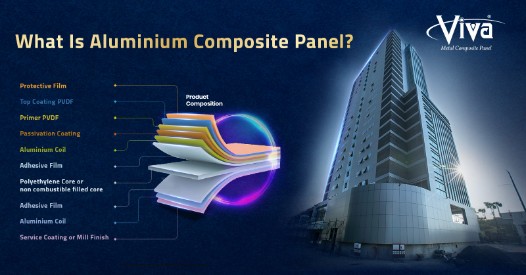

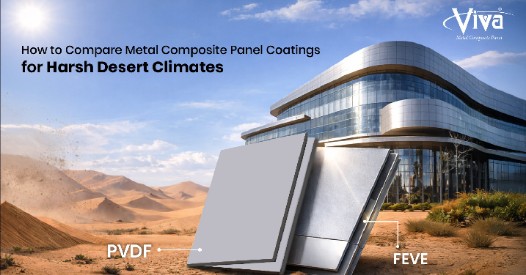

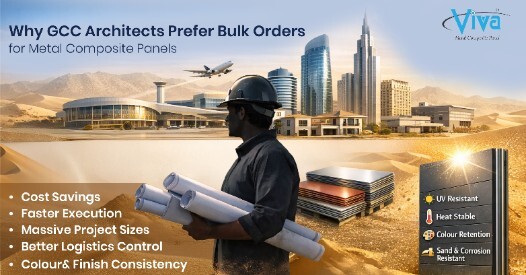

Explore the world of ACP (Aluminum Composite Panels) with our insightful blog, uncovering innovative uses, installation tips, and the latest trends in architectural design.

21-Jan-2026

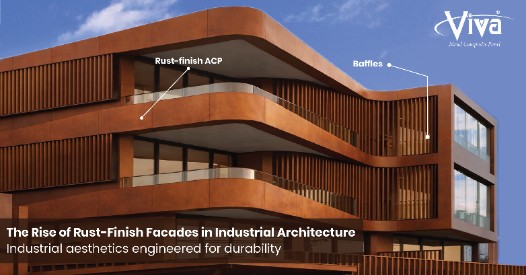

Why Industrial Architecture Is Opting for Rust-Finish Aluminum Composite Sheet

Read More23-Dec-2025

Raising the Bar: India’s First In-House A2 Core Production Facility by Viva Metal Composite Panel Pvt. Ltd.

Read More23-Dec-2025

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French