Aluminium Composite Panels (ACP) has been a popular material for building facades as well as cladding for more than two decades. ACP consists of two high-strength aluminium sheets which sandwich a low density, insulating core. Hence, they are also known as sandwich panels.

The original purpose behind their design and creation was to use it as a material for signage. However, today ACP find diverse applications like wall coverings, architectural claddings, interior decorations, false ceilings, etc.

So, below is the history and evolution of ACP and how it came to become one of the most important building material used in various construction and architectural projects.

History of ACPs

The

aluminium composite panels (ACPs) were originally introduced as a joint invention between companies known as Alusingen and BASF in 1969. Later Alusuisse bought Alusingen, which was eventually obtained by another international firm named Alcan (currently Rio Tinto) in 2000.

In spite of its introduction in the 1960s, it was only until the mid-1980s that the mainstream architectural industry discovered the properties of ACP as a building material and started its extensive use. Moreover, the widespread use of ACP in commercial and residential buildings began in the early 1990s. It was then realised that it could reduce costs and enhance architectural performance.

You May Like: Aluminium Composite Panel And Its Importance

ACP Brands Through Time

The first form of Aluminium Composite Panels that came to existence was marketed under the brand name ‘Alucobond®,’. The manufacturing process was patented by Alusingen for 20 years, between 1971 and 1991. The brand name (Aluminium –Composite — Bonding) was itself a representation of how the panel was made; by bonding the aluminium alloy to a composite material. It is for the same reason that the original aluminium composite panels were also known as Alucobond.

After the patent expired, many prominent names of the construction industry began the ACP manufacturing process. As a result, several significant brands emerged, like Alcoa (brand name Reynobond), Mitsubishi (brand name Alpolic), Etem (brand name Etalbond), etc.

Change in Composition Over The Years

Even though many ACP brands emerged, the product did not change in essence. Significant changes occurred in the composition of the aluminium panels, which were modified based on the required features of the panel and their area of use.

However, when some high-rise buildings got burnt due to the involvement of ACP sheets, the flammable nature of its core material came to the fore. Since then, the core material has been altered to constitute non-flammable material with a low combustion risk.

You May Like: Aluminum Composite Panel (ACP) Design, Features and Uses

The overall thickness of the panels used currently is in the range of 3-6 mm (0.12-0.24 in.), and that of the aluminium facings is in the range of 0.2- 0.8 mm (0.008- 0.032 in.) The insulated core has been developed from several different materials, but there are three general categories today in which every kind of core belongs:

- PE Cores – These cores are made of 100% polyethylene (PE) and are flammable.

- FR Cores – These cores are made of a composite material containing a high percentage (70% to 90%) of mineral wool/ rock fiber/ rock wool, which are non-combustible and act as a fire retardant.

- Aluminium Cores – These cores are either made of an aluminium honeycomb structure or solid aluminium.

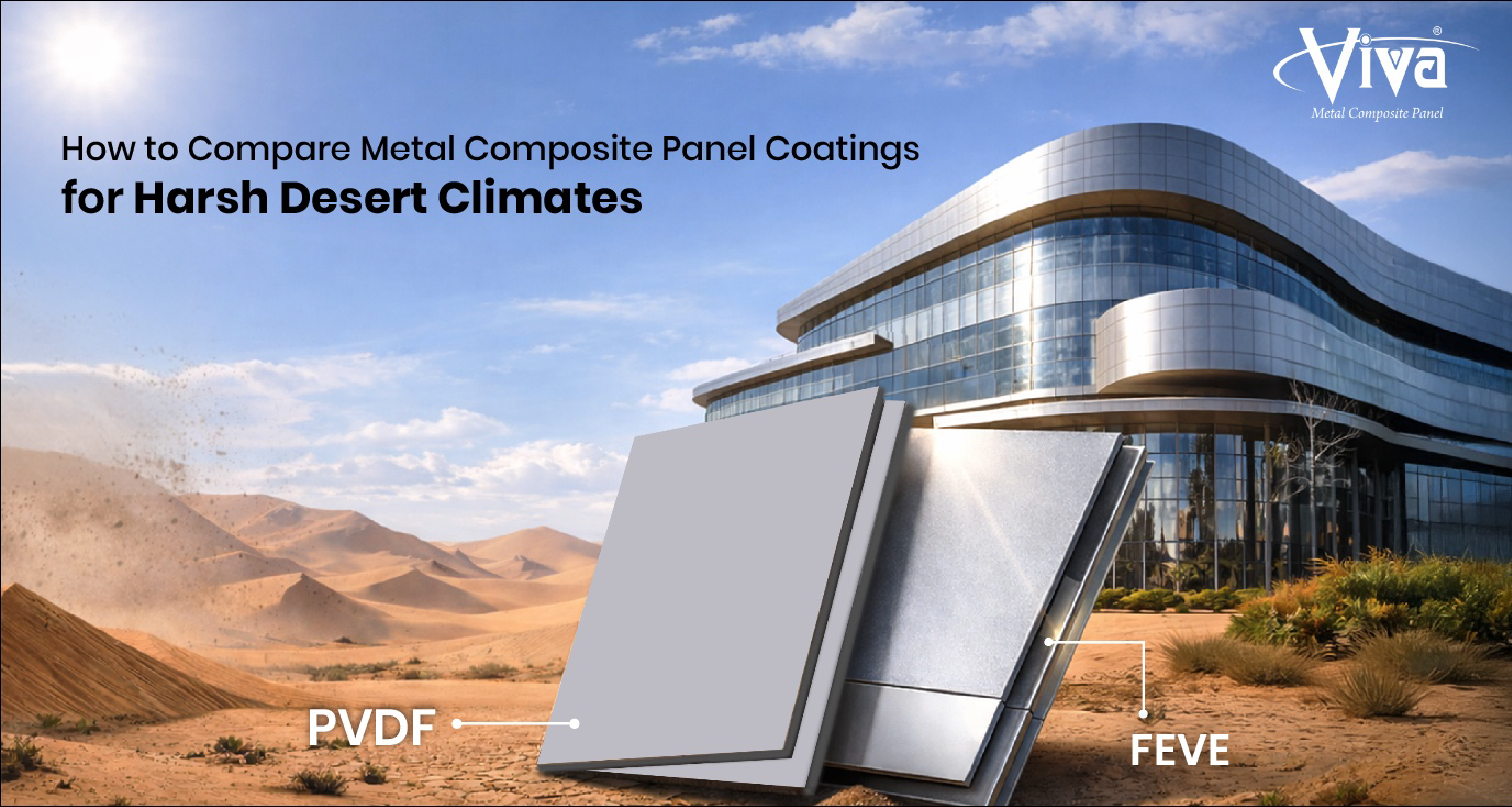

To make them more suitable for various kinds of applications, ACPs have been developed with different types of paints and coatings, as shown below:

- PE/FR Constructional/Architectural Panel sheets coated with PVDF resin, (XT/ High Durable) polyester paint.

- Panel sheets coated with Nano PVDF

- Digital Printing/ Signage Panel sheets coated with FEVE resin or high-quality polyester.

Since the modifications carried out with the core and panel quality, several

ACP products have been launched which show many architectural advantages over other building materials:

- Higher-strength-to-weight ratio

- Lighter weight

- The material flexibility and adaptability

- Durability

- Superior insulation features

Evolution of ACP Panels

From being used for signage in the beginning to being a major architectural material, ACP has come a long way. Today, it finds applications in various projects and spaces, including in:

Internal Partitions, Building Renovations, Curved Fascias, Container Constructions, Internal Wall Coverings, Architectural Claddings, Machine Coverings and many more.

The panels are one of the most used material that dominates the facade industry. Due to its lightweight features, it is the substance of choice for building temporary elements like trade show structures. Viva manufactures high-quality Aluminum composite panels as per the building requirements. These include Aluminum core, FP core and PE core sandwich material that gives maximum structural integrity and fire hazard protection.

The use of the panels has evolved to such a level that many famous architectural marvels are extensively constructed from it. Some of them are Spaceship Earth in Orlando (U.S.); the L’Oreal Paris building in France; the Guggenheim Museum Bilbao; The Leipzig branch of the German National Library; VanDusen Botanical Garden in Canada, etc.

Conclusion

From a material dominated by a single company, composite panels have evolved not only in their composition and manufacturers but also in its applications, making it one of the most used materials in the construction and architectural industry. With their lighter weight and fire-retardant properties, they have been used so extensively, that some modern cities are composed entirely of them, along with materials like glass and curtain walls.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French