When it comes to adding aesthetic value or longevity to a building, AHPL outshines its alternatives. AHPL is the acronym for Aluminium High-Pressure Laminates. The panels originate from the idea of an HPL sheet, which is manufactured by high-pressure paper into laminates. In AHPL, paper is replaced by Aluminium, and manufactured like ACP panels.

The durability and sturdiness are several reasons why AHPL cladding is gaining popularity. The panels are available in a range of textures, hues, and designs that certainly dramatically alter any structure.

In this blog, we will help you understand how AHPL is better than other composite materials and how Viva is adding value to the construction industry with this material.

Why it is wise to install AHPL as Building Cladding?

This is a checklist that lists some of the common reasons for choosing AHPL, manufactured from ACP sheet as preferable material in the construction industry.

Durability

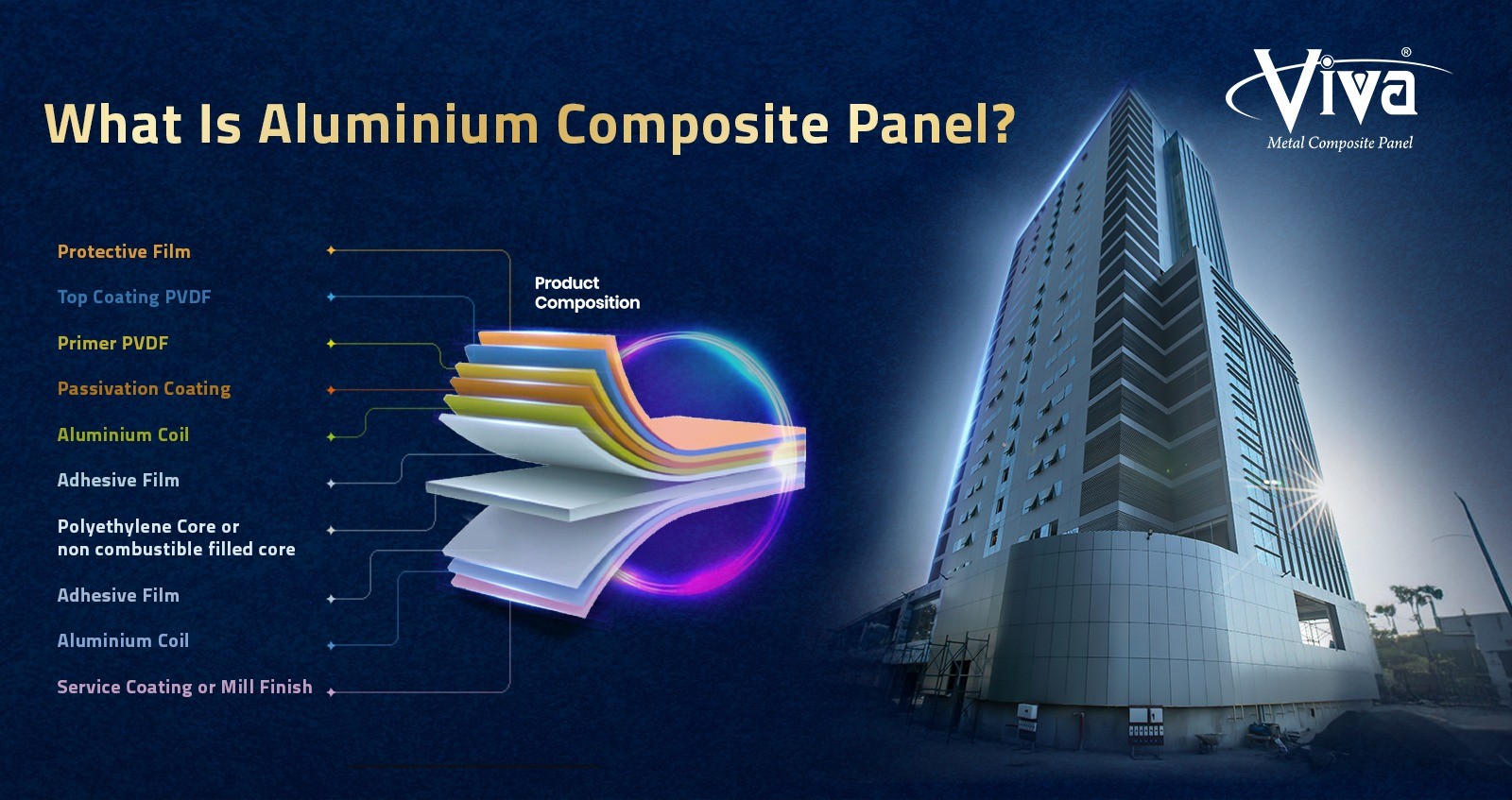

AHPL sheets are 6mm and 8mm, the thickness of these panels makes them sturdier. The panels comprise of aluminium alloy coil on both sides that sandwich the thermoplastic core in between.

The panels have high impact resistance, and the ability to resist stress. The high-pressure absorption and ability to resist damage that allows scratch, stain, and overheating of panels make it a superior choice.

Our AHPL sheet has longevity of over 25 years if installed properly, while it decreases to 20 years in the marine environment or with poor installation.

Flexible in Use

When evaluating the application of AHPL in building cladding, it appears to be fit for use in every corner. The panels are similar in the characteristic of ACP sheet, which means, it is 90-degree bendable, and easy to fabricate.

You May Like: Why Is AHPL The Right Choice For Cladding?

The use of a router and mica knife is enough to make cuts to shape the panels into a circle, rectangle, or square. It helps in giving the artistic liberty to designers to create unique and creative designs with material that does not limit itself because of a lack of flexibility.

Ditch the experts for maintenance

While planning and designing high-rise buildings for modern luxury resorts, maintenance is the key factor that influences the choice of material and even the hues in exterior cladding.

As the ACP sheets are protected from dust, dirt, debris, and pollutants with their protective layering, i.e powder coating, the same phenomenon is done while manufacturing AHPL panels. We use 70% KYNAR 500 certified paint that confirms ASTM standards. Along with that, we also use FEVE-based paint for exterior application.

Our PVDF paint has anti-aging properties, while FEVE adds shine to the panels. These coatings ensure there is a minimal requirement for maintenance in the sheets. If required, you can always clean the panel using light detergent and water.

Aesthetic Factor

AHPL is a great addition to building cladding, as it magically transforms the outlook of any structure. The panels are highly attractive and they can retain their shine for ages. This is because of powder coating.

The coating comes in a range of colours, textures, and patterns. However, mostly AHPL sheets are available in wooden texture. Some of our panels that can elevate your décor are VA9004 Versace Brown, VA9005 Ferrari Red, VA9003 Charminar Red, and many more.

Why choose Viva?

Viva is a leading AHPL manufacturing company in India. We procure aluminium alloy from leading aluminium manufacturing companies in India, which are processed with a thermoplastic core in the manufacturing plant of Umbergaon.

Apart from AHPL, we have a wide range of products available in over 300 colours and shades. We have a Zinc composite panel, LDPE core ACP panel, honeycomb panel, and fire-retardant panel.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French