For decades, traditional materials like timber, brick, and metal have been staples in building facades. However, aluminium cladding has emerged as a preferred choice in modern architecture due to its lightweight nature, exceptional functionality, and long-lasting durability.

Available in a wide range of colours, textures, and finishes, aluminium cladding offers versatile design possibilities while ensuring a durable, high-performance exterior. In this blog, we will explore the aluminium cladding system and its growing significance in contemporary architectural design.

What is an Aluminium Cladding Sheet?

An aluminium cladding sheet is a thin layer of aluminium that is used to cover the exterior walls of a building. In the construction sector, aluminium cladding sheets are used for their physical and chemical properties.

Their use case has increased as they provide protection against atmospheric agents and reduced solar radiation. Additionally, they are corrosion-resistant and hence can be used on the exterior.

Different Types of Aluminum Cladding Systems

Aluminium cladding systems come in various forms. Two widely used types include:

-

Aluminum Composite Panels (ACM Panels or ACP Material)

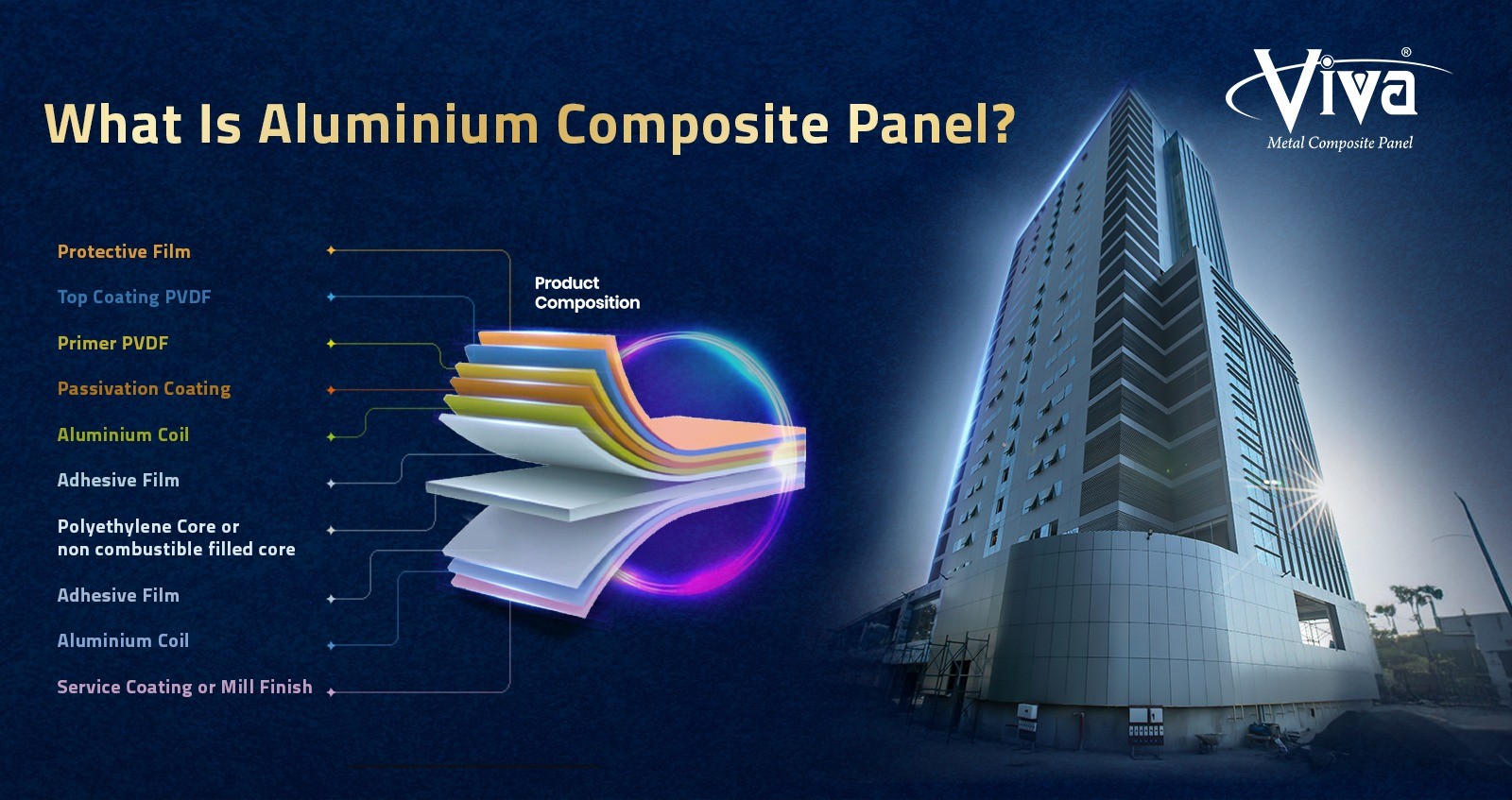

- ACPs are made by sandwiching a non-aluminium core between two aluminium sheets.

- Known for being lightweight, durable and weather-resistant, ACPs are ideal for both interior and exterior applications.

-

Aluminum Siding

- This cladding type is used in new residential buildings. It consists of horizontal or vertical stripes of aluminium, providing a traditional look.

- Easy maintenance and is available in various colours and textures.

Aluminium Cladding Systems Advantages and Benefits

- Durability: Aluminium is known for its durability and agility despite being lightweight. It can withstand harsh weather conditions and hence it is an ideal choice for cladding systems.

- Low Maintenance: Aluminium cladding sheets are resistant to rust, corrosion, and discolouration, making them less prone to repairs and replacement. This makes them low-maintenance and, hence, a popular choice.

- Fire resistant: Aluminium has a high melting point and is also non-combustible; hence, it is highly fire resistant and safe.

- Energy Efficiency and Sustainability: Aluminium cladding minimises heat transfer between interior and exterior and acts as a barrier against heat loss or gain, resulting in decreased dependency on heating and cooling.

- Versatility: Aluminium cladding sheets are available in different shapes, structures, colours and designs, making them more popular among architects who envision creating a more aesthetically pleasing exterior.

- Cost-Effective and Easy Installation: Aluminium cladding sheets prove to be more cost-effective in the long run. Not only are they easy to install and handle, but they also show longevity in terms of anti-corrosion and are resistant to rust and discolouration.

Aluminium Cladding Panels Installation Process

- Preparation: Check and clean the exteriors of the building to ensure a smooth surface for installation.

- Framework Setup: Start by installing a supporting framework, ideally made out of aluminium or steel, to secure the mechanical fasteners.

- Fabricate the panels: Use electric saws to cut the ACP sheets into neat, right cuts. Once the sheets have been cut, grooving is carried out, after which the panels are folded.

- Waterproofing: Once the sheets have been fabricated and folded, waterproofing needs to be carried out by creating an air vapour barrier and installing a rain-screen system.

- Flashing: Waterproofing is completed only when the substrate is flashed down. Flashing the gutter enhances the flow of water from the building.

- Grid: The purpose of the grid is to make sure that the ACP sheets are installed in a uniform and appealing manner.

- Mounting of Panels: Attaching the aluminium composite panel cladding to the framework using screws, industrial adhesive or mechanical fasteners.

- Peeling off the protective layer: After the installation is done, peel off the protective layer to reveal the beautiful sheet inside.

Aluminium Cladding Maintenance and Cleaning

- Regular Cleaning: To clean your aluminium composite panel cladding, use mild detergent and a soft cloth to remove dust and dirt without scratching.

- Repainting: Repainting your sheets can help restore the initial beauty and shine of your aluminium sheet.

Conclusion

The aluminium cladding sheet has become a popular preference in modern architecture. With proper installation and careful maintenance, aluminium cladding sheets can significantly enhance the exteriors of your building.

Choose the right aluminium cladding sheet for your building from Viva ACP. We offer high-quality aluminium cladding sheets that combine durability and increase the aesthetic appeal of your project.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French