Renowned for its commitment to quality and innovation, Viva ACP, Asia's largest manufacturer and supplier of Metal Composite Panels (MCPs), has been pushing the boundaries of architectural excellence for 25 years .

Following a rigorous manufacturing process driven by cutting-edge technology, precision engineering, and robust quality control checks, Viva ACP delivers groundbreaking MCP solutions trusted by architects, designers, builders, and homeowners all over the world.

In this exclusive behind-the-scenes look, we invite you to explore the process that defines Viva ACP’s manufacturing excellence, from conception to its execution.

The Making of Metal Composite Panels: Viva ACP’s Journey to Perfection

Raw Material Sourcing

The first contributor to Viva ACP’s manufacturing excellence is its choice of raw material sourcing. Viva ACP procures paints, adhesives, and aluminium coils from certified and trusted sources, including, but not limited to:

- Nippon Paints: A Japanese paint and paint products manufacturing company.

- DuPont: An American Conglomerate that provides specialised materials.

- Hindalco: One of India’s biggest aluminium manufacturing companies.

Precision Engineering

Viva ACP’s manufacturing facilities boast 12 advanced ACP production lines where modern technology converges with expert craftsmanship and quality materials.

The company’s state-of-the-art production lines manufacture both fire-retardant and non-fire-retardant ACP panels and are divided into 3 categories, including:

- FR Class B: This line produces cores comprising 70% mineral and 30% polyethylene, suitable for interior and exterior applications.

- FR Class A2: This line produces cores comprising 90% mineral and 10% polyethylene, which is ideal for hospitals, schools, museums and skyscrapers.

- FR Class A2+: This line produces a honeycomb core sandwiched between two aluminium coils. It is best suited for high-end architectural applications demanding excellent strength, structural integrity, and durability.

Colour Coating

Viva ACP is equipped with four colour coating lines that pretreat and coat aluminium coils, ranging from 1000 mm to 1670 mm, for better paint adhesion and aesthetics.

Under the colour coating process:

1. Aluminium coils are cleaned and passivated which enhances the paint bonding with aluminium.

2. Next, liquid paint is applied over the pretreated coil using the mirror-finished roller coating method.

3. Then, the sheets are dried (baked) at 240°C for nearly 45 seconds to ensure that the coating is completely bonded to the aluminium sheets.

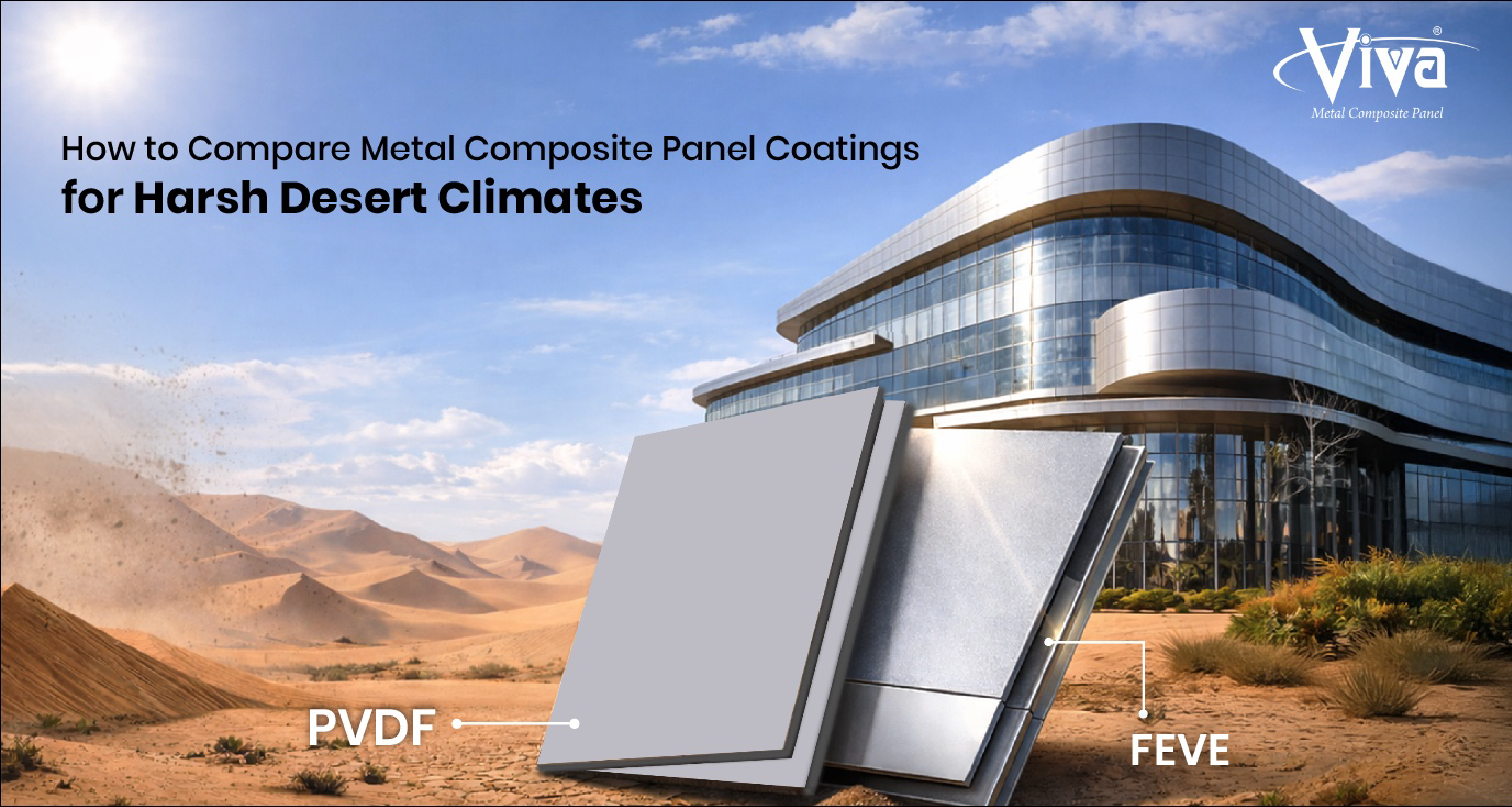

4. Lastly, the top layer of the panels is coated with a protective coating of Polyvinylidene Fluoride (PVDF), a high-performance fluorocarbon resin.

This meticulous coating method produces colour-coated sheets that give Aluminium Composite Panels a distinctive and unique appearance.

Moreover, Viva ACP operates an advanced paint mixing setup that guarantees precise colour matching and consistency. This facility offers:

● The possibility of infinite customisation.

● New shades and pattern finishes, such as glossy, matt, rustic, marble, stone, wooden, etc.

Lab Testing and Quality Checks

Viva ACP has in-house labs and research and development (R&D) centres that equip over 100 pieces to carry out stringent checks on the MCP sheets produced and introduce new products with better features and properties.

These quality control tests enable Viva ACP to guarantee superior quality production of Metal Composite Panels in a wide range of designs , colours, textures, and materials.

Furthermore, these comprehensive checks confirm that Viva ACP panels comply with both national and international standards, surpassing expectations in quality, performance, reliability, durability, and customer safety and satisfaction.

Wrapping Up

With a mission to deliver superior-performance Metal Composite Panels while creating an unforgettable impression on the customers, Viva ACP is a shining example of manufacturing excellence.

From sourcing best-in-class raw materials and using advanced manufacturing technology to long-lasting coating and strict quality control and testing, every step of Viva ACP’s manufacturing process displays an unrelenting passion for perfection.

So, are you ready to discover the ultimate solution for long-lasting, aesthetically appealing and innovative structures? Visit Viva ACP today and explore a whole range of flawless MCPs in just a few clicks.

en

en

Spanish

Spanish Arabic

Arabic Swahili

Swahili French

French